Kia Rio: Maintenance / Engine Oil and Filter

Repair procedures

| Inspection |

Engine Oil Level

Be sure that the vehicle is on level ground. |

| 1. |

Warm up and stop the engine, and then wait for 5 minutes. |

| 2. |

Turn the engine off and wait for a few minutes (about 5 minutes) for the oil to return to the oil pan. |

| 3. |

Pull the dipstick out, wipe and re-insert it fully. |

| 4. |

Check that the oil level is between the "L" level mark and "F" level mark on the engine oil level gauge. |

| 5. |

If the level is low, check for leakage and add oil up to the full level mark.

|

Engine Oil Appearance

| 1. |

Check engine oil for white turbidity or heavy contamination. |

| 2. |

If engine oil becomes turbid and white, it is highly probable that it is contaminated with engine coolant. Repair or replace damaged parts. |

| Replacement |

|

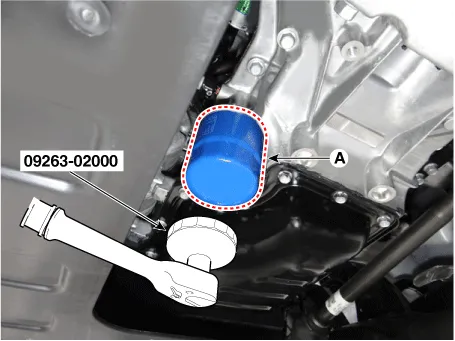

[Kappa 1.0 T-GDI, 1.2 MPI, 1.4 MPI]

| 1. |

Park the car on level ground. |

| 2. |

Drain the engine oil.

|

| 3. |

Replace the oil filter.

|

| 4. |

Install the oil drain plug with a new gasket.

|

| 5. |

Fill with new engine oil, after removing the engine oil level gauge.

|

| 6. |

Install the oil filler cap. |

| 7. |

Start engine and check for oil leaks. |

| 8. |

Recheck the engine oil level. |

| 9. |

To reset the service interval to the recommended mileage, refer to the service mode section in the owner's manual for procedure (if applicable). |

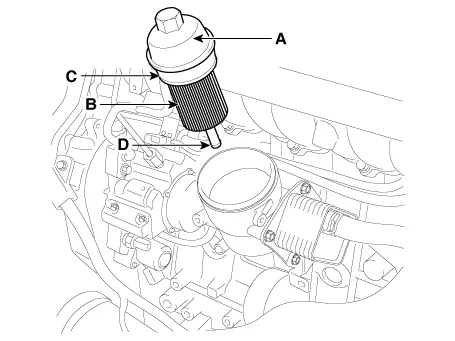

[U-2 1.4 TCI]

| 1. |

Park the car on level ground. |

| 2. |

Drain the engine oil.

|

| 3. |

Replace the oil filter (B).

|

| 4. |

Refill with engine oil.

|

| 5. |

Start engine and check for oil leakage. |

| 6. |

Recheck the engine oil level. |

| 7. |

To reset the service interval to the recommended mileage, refer to the service mode section in the owner's manual for procedure (if applicable). |

- Exhaust System

- Fluid (ATF)

- Fuel Filter (For Diesel engine only)

- Fuel Lines, Hoses and Connections

- Manual Transaxle Oil

- Spark Plug

- Valve Clearance

- Vapor Hose and Fuel Filler Cap

Repair procedures Inspection 1. Check belt for maintenance and abnormal wear of V-ribbed part. Replace if necessary. • Do not bend, twist or turn the drive belt inside out.

Repair procedures Inspection 1. Visually check the pipes, hangers and connections for severe corrosion, leaks or damage.

Other information:

Kia Rio 2017-2023 YB Service Manual: Immobilizer System

Schematic diagrams Circuit Diaram Description and operation Description The immobilizer system will disable the vehicle unless the proper ignition key is used, in addition to the currently available anti-theft systems such as car alarms, the immobilizer system aims to drastically reduce the rate of auto theft.

Kia Rio 2017-2023 YB Service Manual: Auto Defogging Sensor (FATC only)

Description and operation Description The Auto Defogging Sensor is installed on front windshild glass. The Auto Defogging Sensor senses moisture on the windshild. The air conditioner control module receives the signal from the sensor and eliminate the fog by controlling the intake actuator, A/C, auto defogging actuator, blower m

Categories

- Manuals Home

- Kia Rio Owners Manual

- Kia Rio Service Manual

- Engine Oil and Filter

- Battery

- Coolant

- New on site

- Most important about car