Kia Rio: Engine Electrical System / Charging System

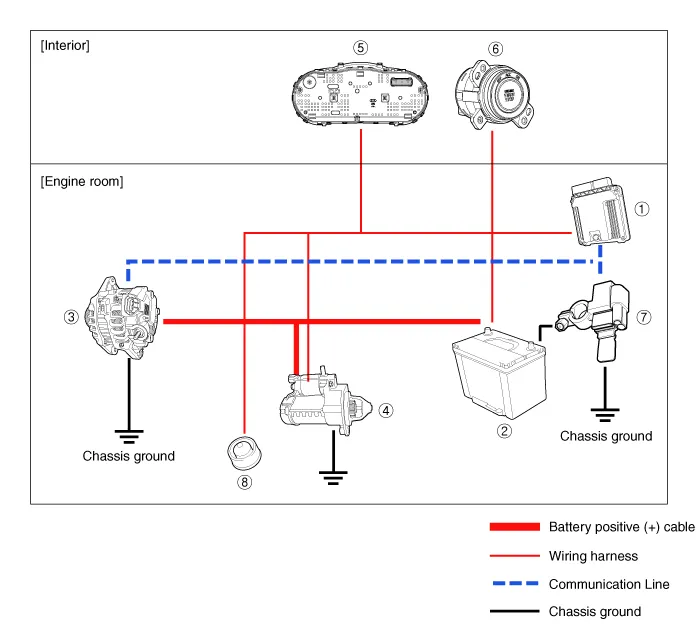

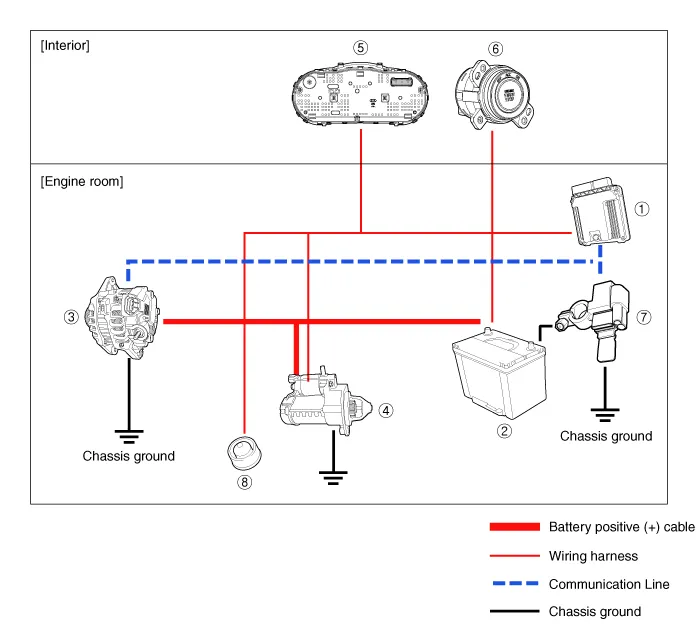

Components and components location

① ECM

② Battery

③ Alternator

④ Starter

⑤ Instrument Cluster

⑥ Ignition switch or start/stop button

⑦ Battery sensor

⑧ Hood switch

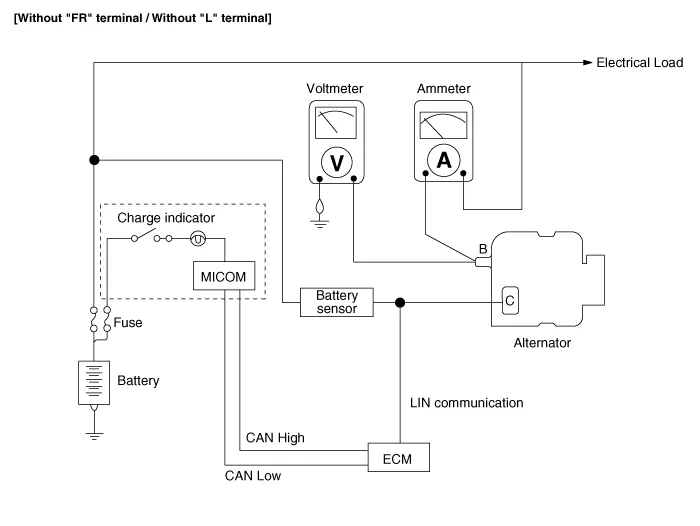

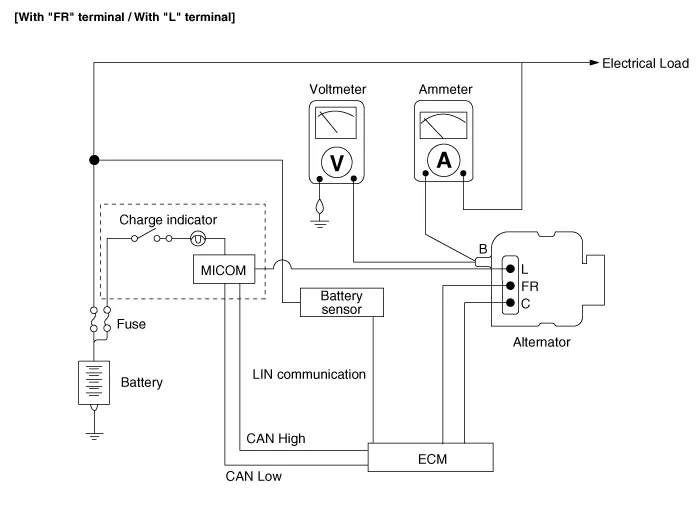

Description and operation

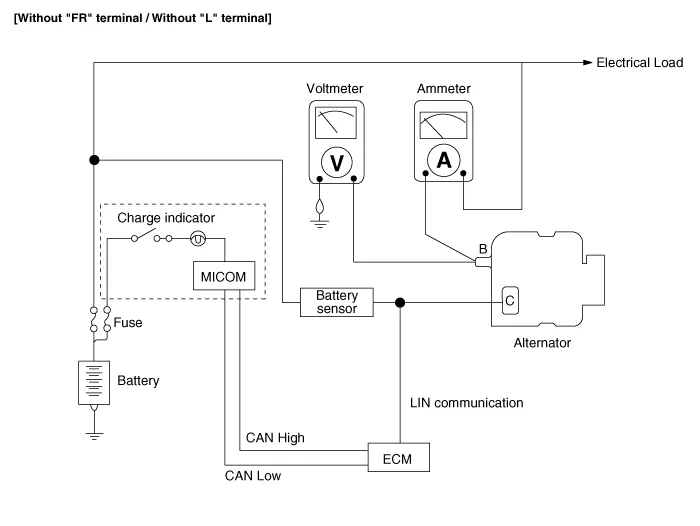

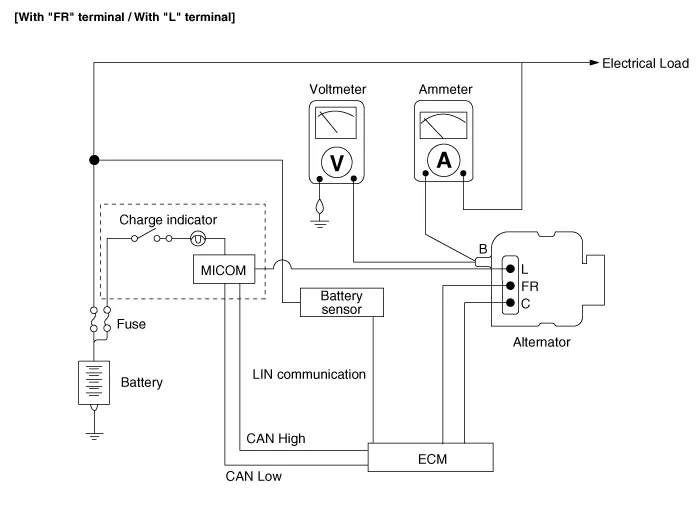

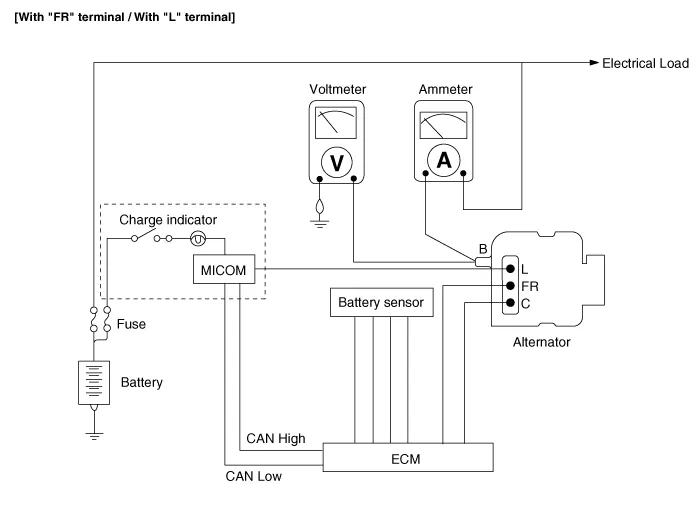

The charging system included a battery, an alternator with a built-in regulator,

and the charging indicator light and wire.

The Alternator has eight built-in diodes, each rectifying AC current to DC current.

Therefore, DC current appears at alternator "B" terminal.

In addition, the charging voltage of this alternator is regulated by the battery

voltage detection system.

The alternator is regulated by the battery voltage detection system. The main

components of the alternator are the rotor, stator, rectifier, capacitor brushes,

bearings and V-ribbed belt pulley. The brush holder contains a built-in electronic

voltage regulator.

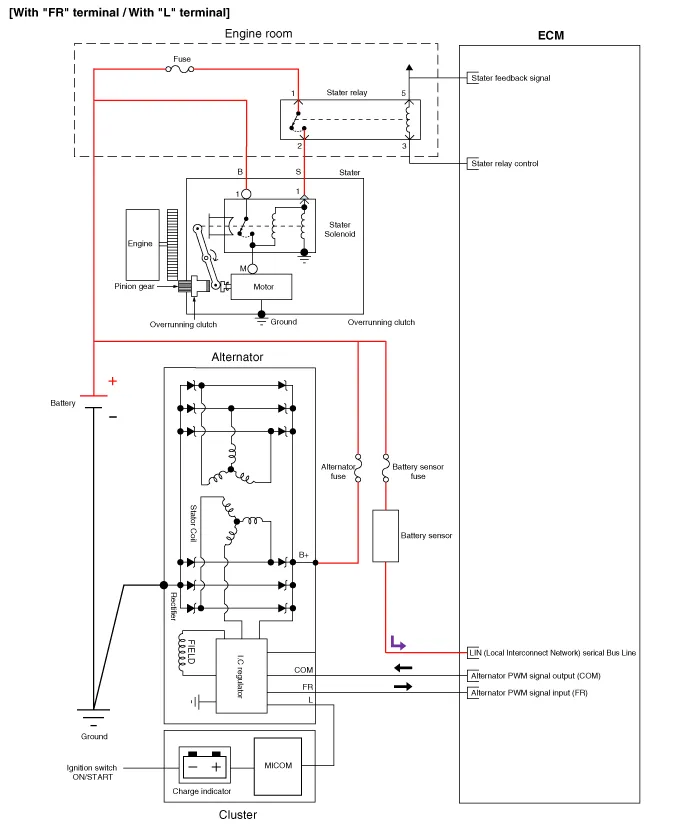

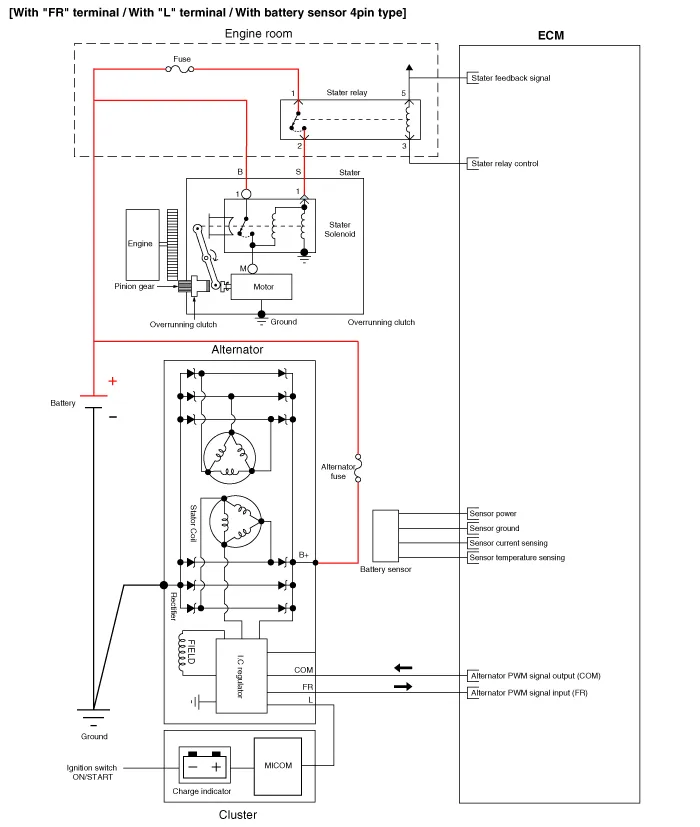

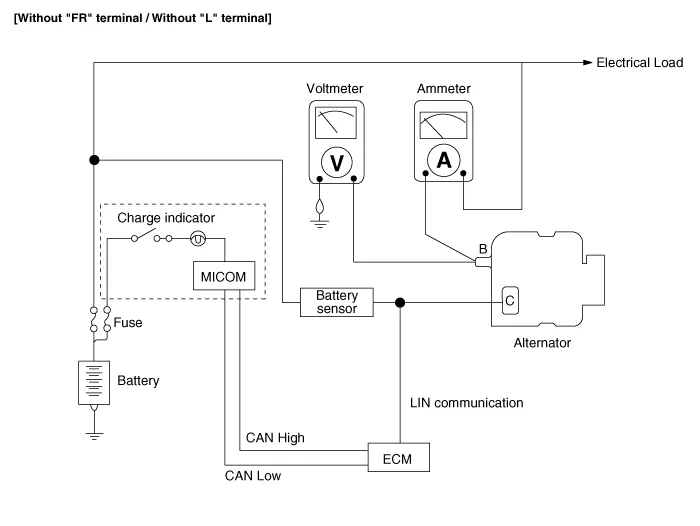

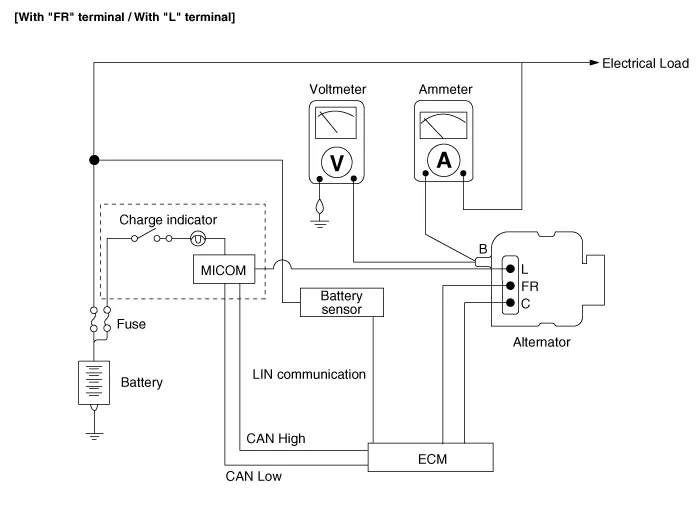

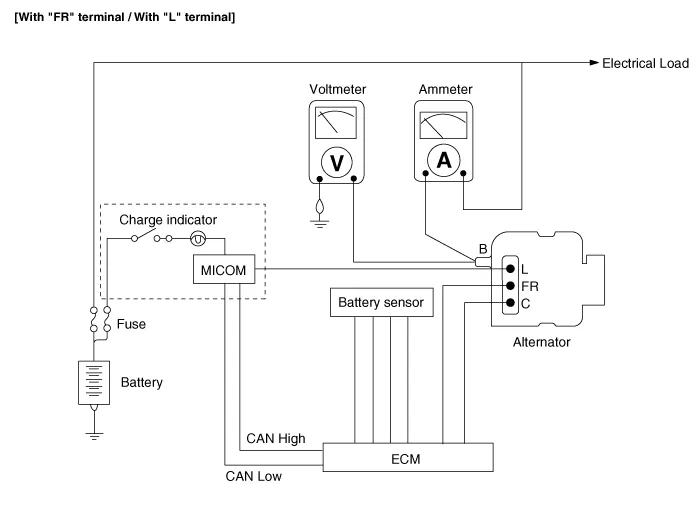

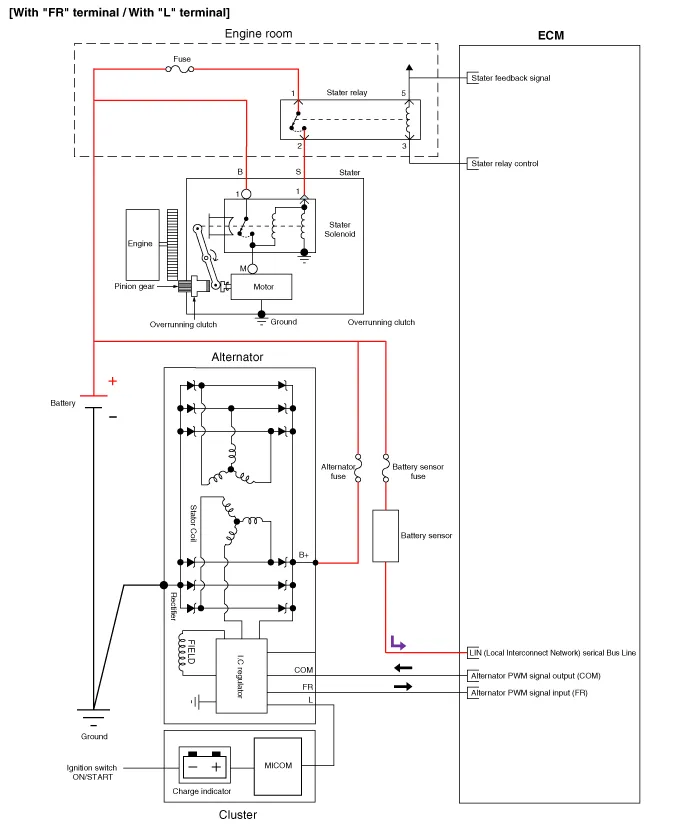

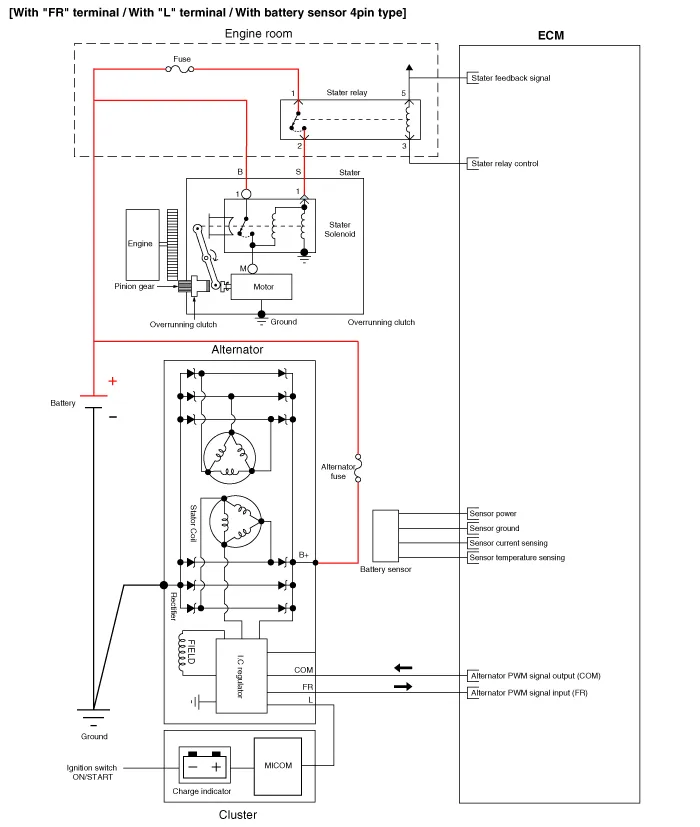

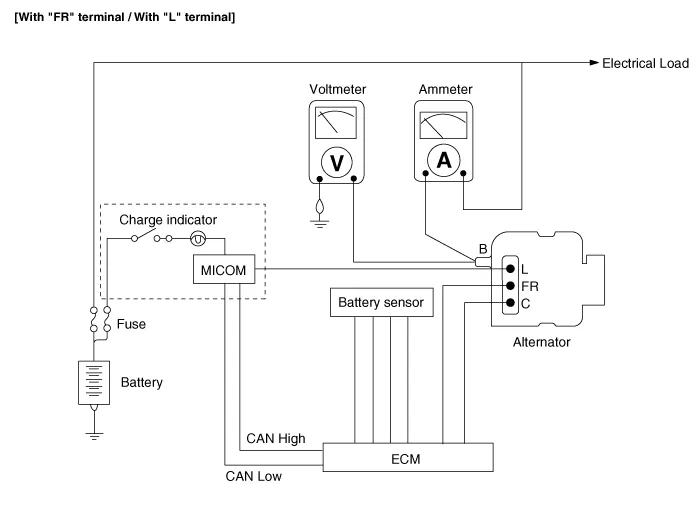

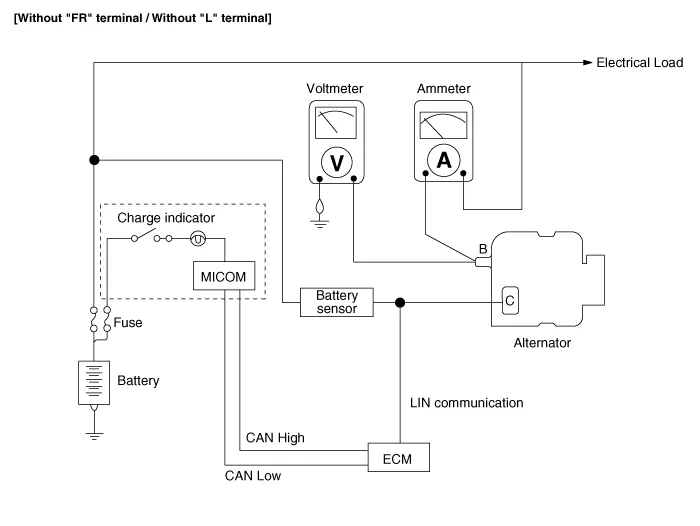

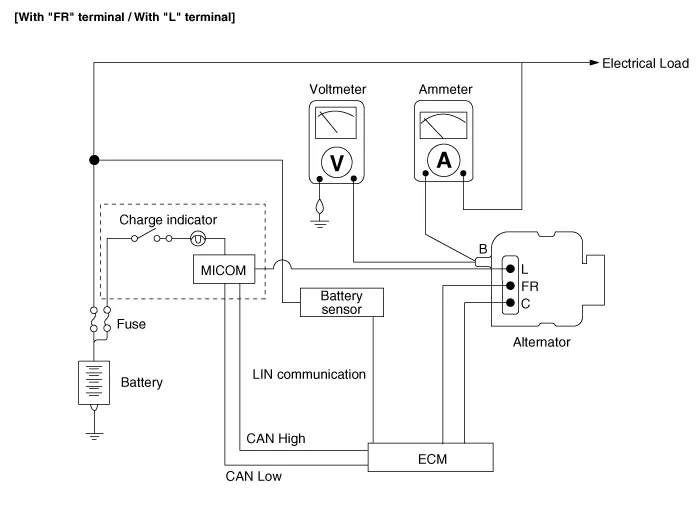

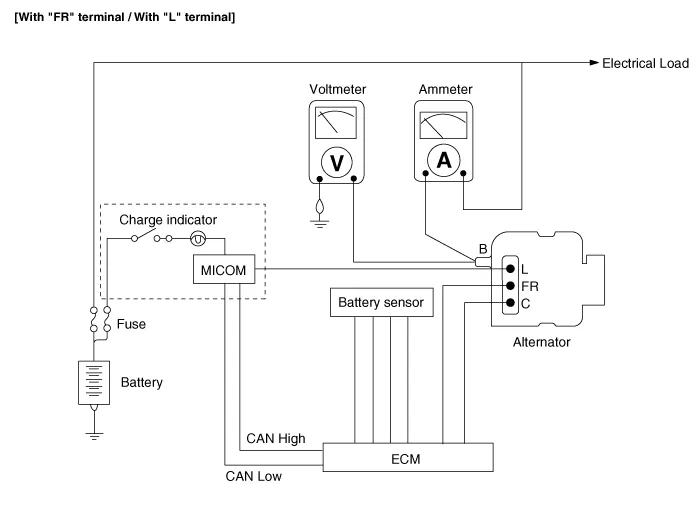

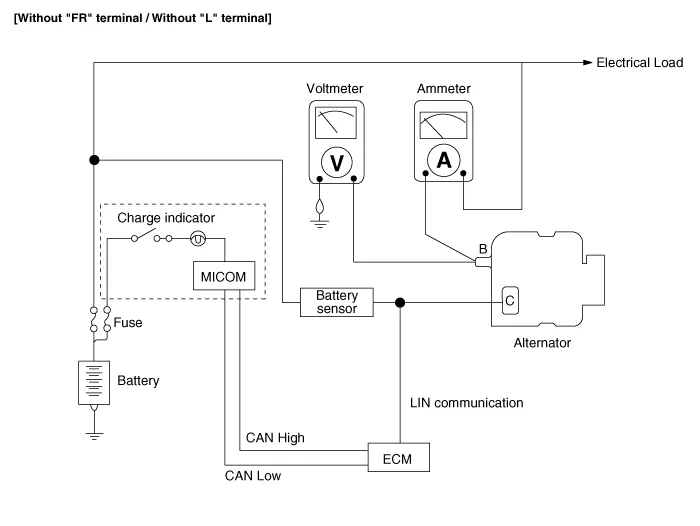

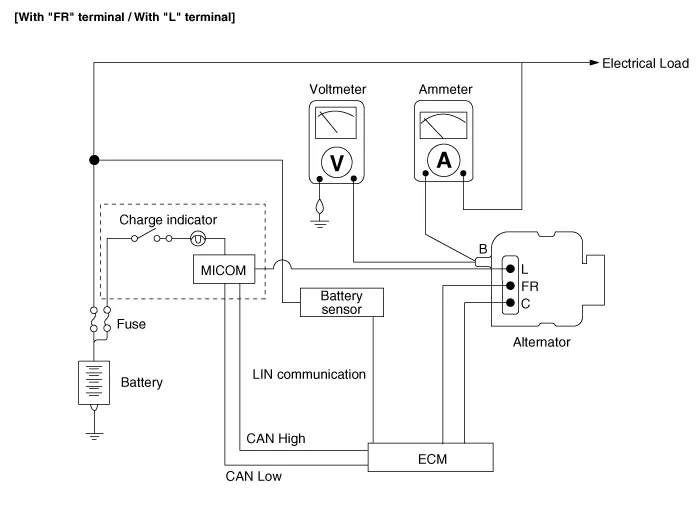

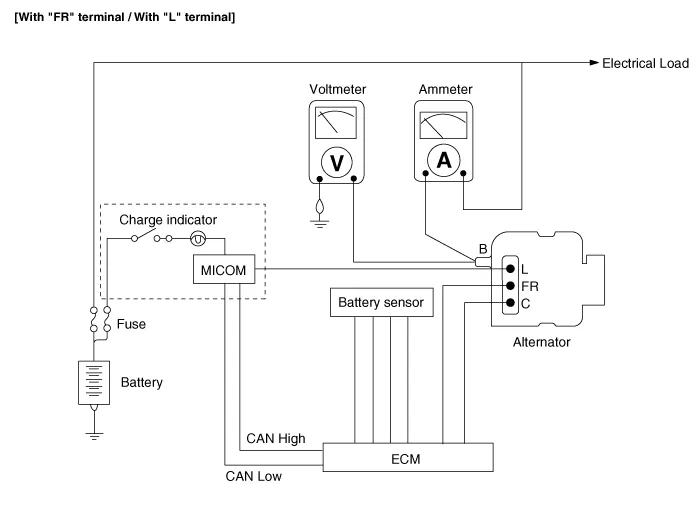

Alternator Management

System

Alternator management system controls the charging voltage set point in order

to improve fuel economy, manage alternator load under various operating conditions,

keep the battery charged, and protect the battery from over-charging. ECM controls

generating voltage by duty cycle (charging control, discharging control, normal

control) based on the battery conditions and vehicle operating conditions.

The system conducts discharging control when accelerating a vehicle. Vehicle

reduces an alternator load and consumes an electric power form a battery.

The system conducts charging control when decelerating a vehicle. Vehicle increases

an alternator load and charges a battery.

Schematic diagrams

Repair procedures

| • |

Battery efficiency inspection

|

| • |

Battery voltage inspection

|

| • |

Charging voltage insptection

|

| • |

Terminal tightening state inspection

|

| • |

Engine/ transaxle ground state inspection

|

| • |

Wiring harness ground state inspection

|

| • |

Electrical Specified Value Inspection

|

| • |

Vehicle parasitic current inspection

|

| • |

Battery capacity inspection

|

Battery Efficiency

Inspection

| • |

Check that the battery cables are connected to the correct terminals.

|

| • |

Disconnect the battery cables when the battery is given a quick

charge.

|

| • |

Never disconnect the battery while the engine is running.

|

|

| • |

Inspect the battery test using the load tester and battery tester.

|

|

Battery Voltage Inspection

| 1. |

After having driven the vehicle and in the case that 20 minutes have

not passed after having stopped the engine, turn the ignition switch ON

and turn on the electrical system (headlamp, blower motor, rear defogger

etc.) for 60 seconds to remove the surface charge.

|

| 2. |

Turn the ignition switch OFF and turn off the electrical systems.

|

| 3. |

Measure the battery voltage between the negative (-) and positive (+)

terminals of the battery.

|

Standard voltage : Approximately 12.5 - 12.9V [20°C (68°F)]

|

If the voltage is less than specification, charge the battery.

|

General Inspection

| 1. |

Check that the battery terminals are not loose or corroded.

(Refer to Charging System - "Battery")

|

| 2. |

Check the fuses for continuity.

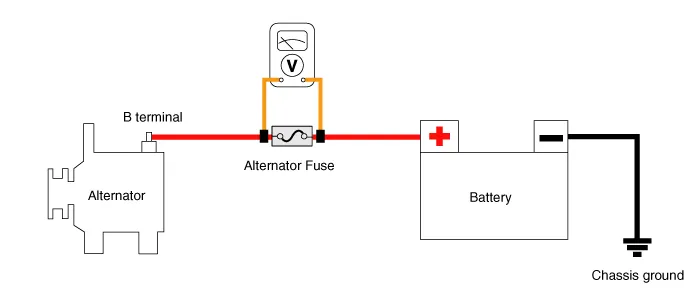

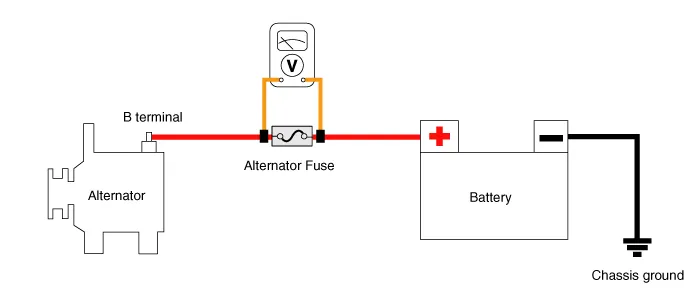

Alternator Fuse

| (1) |

Check the alternator fuse (A) for continuity.

|

| (2) |

Measure the voltage as shown in the image below.

|

Standard value : Approximately 0 V

|

|

| (3) |

If the alternator fuse is blown, replace it as in the procedure

below:

| a. |

Turn ignition switch OFF and disconnect the battery negative

(-) terminal.

|

| b. |

Remove the battery positive (+) cable mounting nuts (A).

|

| c. |

Replace the norminal alternator fuse or battery cable.

|

| d. |

Install in the reverse order of removal.

|

|

|

| 3. |

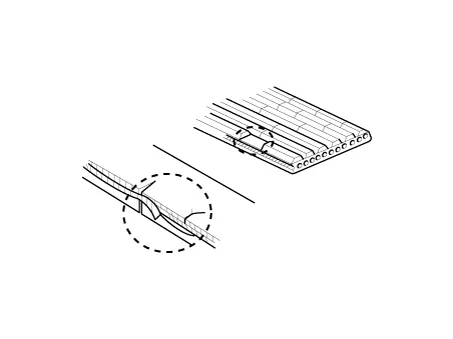

Inspect Drive Belt

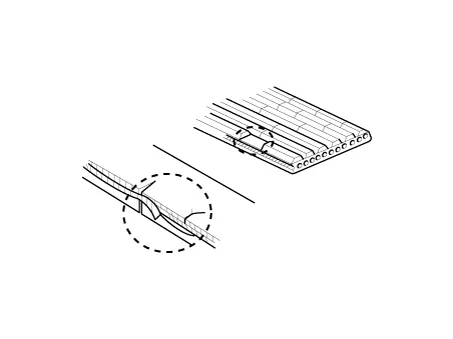

| (1) |

Visually check the belt for excessive wear, frayed cords etc.

If any defect has been found, replace the drive belt.

|

• |

Cracks on the rib side of a belt are considered

acceptable. If the belt has chunks missing from

the ribs, it should be replaced.

|

|

|

|

| 4. |

Measure and adjust drive belt tension.

(Refer to Engine Mechanical System - "Drive Belt")

|

| 5. |

Visually check alternator wiring and listen for abnormal noises.

| (1) |

Check that the wiring is in good condition.

|

| (2) |

Check that there is no abnormal noise from the alternator while

the engine is running.

|

|

| 6. |

Check Discharge Warning Light Circuit

| (1) |

Warm up the engine and then turn it off.

|

| (2) |

Turn off all accessories.

|

| (3) |

Turn the ignition switch "ON". Check that the discharge warning

light is lit.

|

| (4) |

Start the engine. Check that the light is lit.

If the light does not go off as specified, troubleshoot the discharge

light circuit.

|

|

Terminal Tightening

State Inspection

| • |

Alternator B+ terminal state

|

| • |

Alternator B+ termina tightening nut

|

| • |

Battery positive (+) terminal state

|

| • |

Battery positive (+) terminal tightening nut state

|

| • |

Battery negative (-) terminal state

|

| • |

Battery negative (-) terminal tightening nut state

|

| • |

Battery negative (-) terminal mounting bolt tightening state

(Chassis ground)

|

| • |

Battery sensor negative (-) terminal state (With battery sensor)

|

| • |

Battery sensor negative (-) terminal tightening nut state (With

battery sensor)

|

| • |

Battery sensor negative (-) terminal mounting bolt tightening

state (Chassis ground) [With battery sensor]

|

| • |

Engine room fuse & relay box positive (+) harness state

|

| • |

Engine room fuse & relay box positive (+) harness tightening

nut state

|

| • |

Check the status of ground fault by chassis paint

|

|

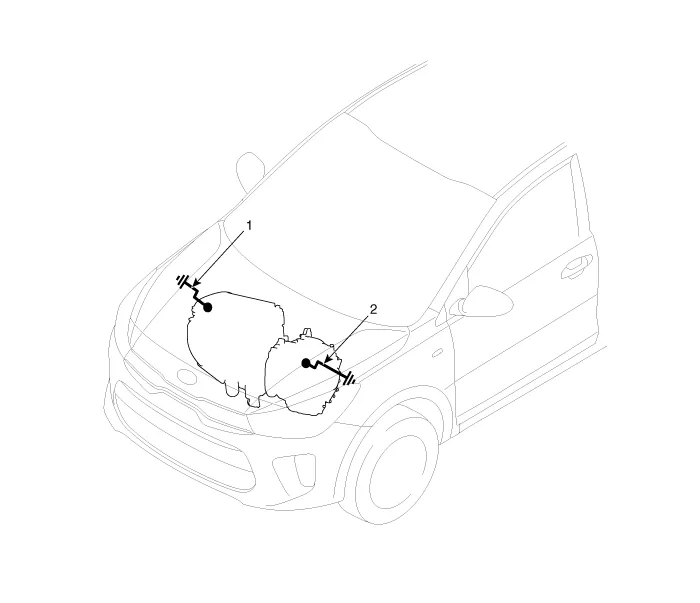

| Inspection Component Location |

1. Alternator B+ terminal

2. Engine room fuse & relay box positive (+) terminal

3. Battery negative (+) terminal

|

4. Battery negative (-) terminal

5. Chassis ground

|

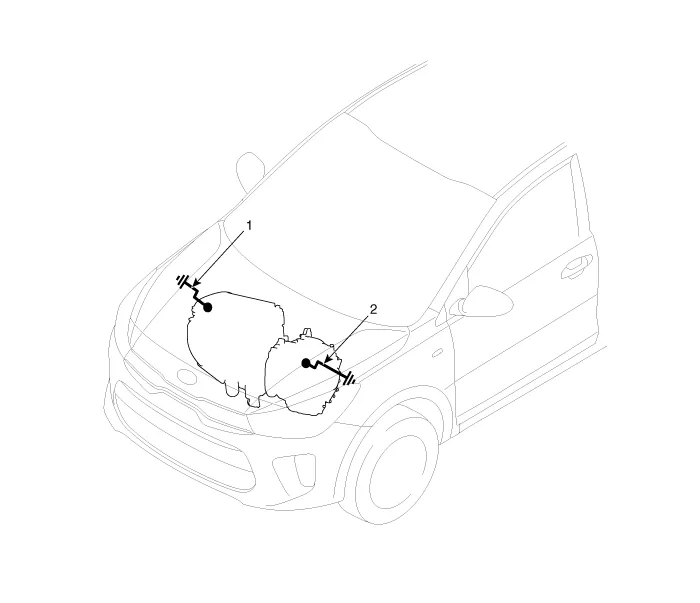

Engine/ Transaxle Ground

State Inspection

| • |

Mounting bolt tightening state (Chassis)

|

| • |

Mounting bolt tightening state (Engine)

|

| • |

Check the status of ground fault by chassis paint

|

|

Wiring harness ground

state inspection

| • |

Mounting bolt tightening state (Chassis)

|

| • |

Mounting bolt tightening state (Engine)

|

| • |

Check the status of ground fault by chassis paint

|

|

1. Engine ground (Engine ↔ Chassis)

2. Transaxle ground (Transaxle ↔ Chassis)

|

|

|

Check the ground point.

(Refer to ETM Harness Layout - "Ground Point")

|

Electrical Specified

Value Inspection (Using the Voltmeter and Ammeter)

| 1. |

Voltage Drop Test of Alternator Output Wire

This test determines whether or not the wiring between the alternator

"B" terminal and the battery (+) terminal is good by the voltage drop method.

| (1) |

Preparation

| a. |

Turn the ignition switch to "OFF".

|

| b. |

Disconnect the output wire from the alternator "B" terminal.

Connect the (+) lead wire of ammeter to the "B" terminal

of alternator and the (-) lead wire of ammeter to the output

wire. Connect the (+) lead wire of voltmeter to the "B"

terminal of alternator and the (-) lead wire of voltmeter

to the (+) terminal of battery.

|

|

| (2) |

Test

| b. |

Turn on the headlamps and blower motor, adjust the engine

speed until the ammeter indicates 20A and read the voltmeter.

|

|

| (3) |

Result

| a. |

The voltmeter may indicate the standard value.

|

Standard value : 0.2V max

|

|

| b. |

If the value of the voltmeter is higher than expected

(above 0.2V max.), poor wiring is suspected. In this case

check the wiring from the alternator "B" terminal to the

battery (+) terminal. Check for loose connections, color

change due to an over-heated harness, etc. Correct them

before testing again.

|

| c. |

Upon completion of the test, set the engine speed at

idle.Turn off the headlamps, blower motor and the ignition

switch.

|

|

|

| 2. |

Output Current Test

This test determines whether or not the alternator gives an output current

that is equivalent to the normal output.

| (1) |

Preparation

| a. |

Prior to the test, check the following items and correct

as necessary.

Check the battery installed in the vehicle to ensure

that it is in good condition. Refer to the "Battery" section

for checking battery.

The battery used to test the output current should be

partially discharged.

With a fully charged battery, the test may not be conducted

correctly due to an insufficient load.

Check the tension of the alternator drive belt. Refer

to the "Inspect drive belt" section for checking the belt

tension.

|

| b. |

Turn off the ignition switch.

|

| c. |

Disconnect the battery ground cable.

|

| d. |

Disconnect the alternator output wire from the alternator

"B" terminal.

|

| e. |

Connect a DC ammeter (0 to 150A) in series between the

"B" terminal and the disconnected output wire. Be sure to

connect the (-) lead wire of the ammeter to the disconnected

output wire.

|

Tighten each connection securely, as a heavy

current will flow. Do not rely on clips.

|

|

| f. |

Connect a voltmeter (0 to 20V) between the "B" terminal

and ground. Connect the (+) lead wire to the alternator

"B" terminal and (-) lead wire to a good ground.

|

| g. |

Connect the battery ground cable.

|

| h. |

Leave the engine hood open.

|

|

| (2) |

Test

| a. |

Check to see that the voltmeter reads the same value

as the battery voltage. If the voltmeter reads 0V, open

circuit in the wire between alternator "B" terminal and

battery (+) terminal or poor grounding is suspected.

|

| b. |

Start the engine and turn on the headlamps.

|

| c. |

Set the headlamps to high beam and the heater blower

switch to HIGH, quickly increase the engine speed to 2,500

rpm and read the maximum output current value indicated

by the ammeter.

|

• |

After the engine start up, the charging

current quickly drops. Therefore, the above

operation must be done quickly to read the

maximum current value correctly.

|

|

|

|

| (3) |

Result

| a. |

The ammeter reading must be higher than the limit value.

If it is lower despite the alternator output wire is in

good condition, remove the alternator from the vehicle and

test it.

|

Limit value : 60% of the voltage rate

|

|

• The nominal output current value is shown on

the nameplate affixed to the alternator body.

|

|

• |

The output current value changes with

the electrical load and the temperature

of the alternator itself. Therefore, the

nominal output current may not be obtained.

If such is the case, keep the headlamps

on to discharge the battery or use lights

of other vehicles to increase the electrical

load.

The nominal output current may not be

obtained if the temperature of the alternator

itself or ambient temperature is too high.

In such a case, reduce the temperature before

testing again.

|

|

|

| b. |

Upon completion of the output current test, lower the

engine speed to idle and turn off the ignition switch.

|

| c. |

Disconnect the battery negative (-) terminal.

|

| d. |

Remove the ammeter and voltmeter and the engine tachometer.

|

| e. |

Connect the alternator output wire to the alternator

"B" terminal.

|

| f. |

Connect the battery negative (-) terminal.

|

|

|

| 3. |

Regulated Voltage Test

The purpose of this test is to check that the electronic voltage regulator

controls voltage correctly.

| (1) |

Preparation

| a. |

Prior to the test, check the following items and correct

if necessary.

Check that the battery installed on the vehicle is fully

charged. Refer to the "Battery" section for checking the

battery.

Check the alternator drive belt tension. Refer to the

"Inspect drive belt" section for checking the belt tension.

|

| b. |

Turn ignition switch to "OFF".

|

| c. |

Disconnect the battery negative (-) terminal.

|

| d. |

Connect a digital voltmeter between the "B" terminal

of the alternator and ground. Connect the (+) lead of the

voltmeter to the "B" terminal of the alternator. Connect

the (-) lead to good ground or the battery (-) terminal.

|

| e. |

Disconnect the alternator output wire from the alternator

"B" terminal.

|

| f. |

Connect a DC ammeter (0 to 150A) in series between the

"B" terminal and the disconnected output wire. Connect the

(-) leadwire of the ammeter to the disconnected output wire.

|

| g. |

Connect the battery negative (-) terminal.

|

|

| (2) |

Test

| a. |

Turn on the ignition switch and check to see that the

voltmeter indicates the following value.

|

Voltage : Battery voltage

|

If it reads 0V, there is an open circuit in the wire

between the alternator "B" terminal and the battery and

the battery (-) terminal.

|

| b. |

Start the engine. Keep all lights and accessories off.

|

| c. |

Run the engine at a speed of about 2,500 rpm and read

the voltmeter when the alternator output current drops to

10A or less

|

|

| (3) |

Result

| a. |

If the voltmeter reading doesn't agree with the standard

value, the voltage regulator or the alternator is faulty.

|

Regulated Voltage : 11.7 - 15.3V

|

|

| b. |

If the voltmeter reading doesn't agree with the standard

value, the voltage regulator or the alternator is faulty.

|

| c. |

Disconnect the battery negative (-) terminal.

|

| d. |

Remove the voltmeter and ammeter.

|

| e. |

Connect the alternator output wire to the alternator

"B" terminal.

|

| f. |

Connect the battery negative (-) terminal.

|

|

|

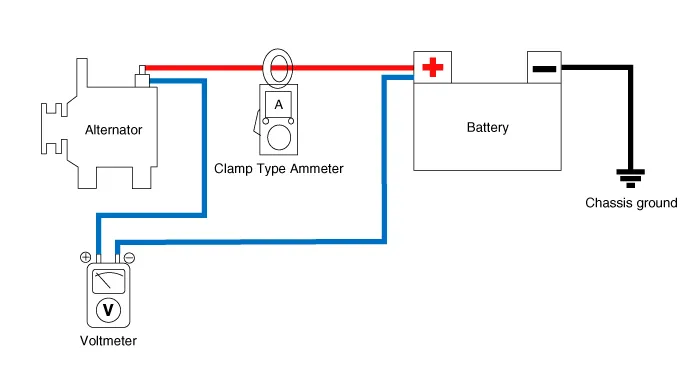

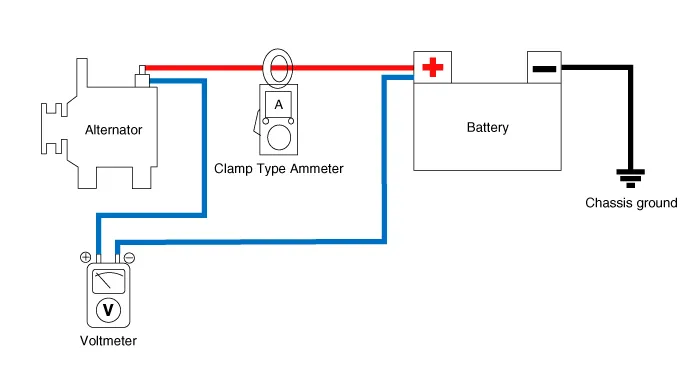

Electrical Specified

Value Inspection (Using the Voltmeter and Clamp type Ammeter)

| 1. |

Voltage Drop Test of Alternator Output Wire

This test determines whether or not the wiring between the alternator

"B" terminal and the battery (+) terminal is good by the voltage drop method.

| (1) |

Preparation

| a. |

Turn the ignition switch to "OFF".

|

| b. |

Install the clamp type ammeter between battery positive

(+) and alternator "B" terminal.

|

| c. |

Connect the (+) lead wire of voltmeter to the "B" terminal

of alternator and the (-) lead wire of voltmeter to the

(+) terminal of battery.

|

|

| (2) |

Test

| b. |

Turn on the headlamps and blower motor, adjust the engine

speed until the ammeter indicates 20A and read the voltmeter.

|

|

| (3) |

Result

| a. |

The voltmeter may indicate the standard value.

|

Standard value : 0.2V max

|

|

| b. |

If the value of the voltmeter is higher than expected

(above 0.2V max.), poor wiring is suspected. In this case

check the wiring from the alternator "B" terminal to the

battery (+) terminal. Check for loose connections, color

change due to an over-heated harness, etc. Correct them

before testing again.

|

| c. |

Upon completion of the test, set the engine speed at

idle.Turn off the headlamps, blower motor and the ignition

switch.

|

|

|

| 2. |

Output Current Test

This test determines whether or not the alternator gives an output current

that is equivalent to the normal output.

| (1) |

Preparation

| a. |

Prior to the test, check the following items and correct

as necessary.

Check the battery installed in the vehicle to ensure

that it is good condition. Refer to the "Battery" section

for checking the battery.

The battery used to test the output current should be

partially discharged.

With a fully charged battery, the test may not be conducted

correctly due to an insufficient load.

Check the tension of the alternator drive belt. Refer

to the "Inspect drive belt" section for checking the belt

tension.

|

| b. |

Turn off the ignition switch.

|

| c. |

Disconnect the battery negative (-) terminal.

|

| d. |

Install the clamp type ammeter between battery positive

(+) and alternator "B" terminal.

|

| e. |

Connect a DC ammeter (0 to 150A) in series between the

"B" terminal and the disconnected output wire. Be sure to

connect the (-) lead wire of the ammeter to the disconnected

output wire.

|

Tighten each connection securely, as a heavy

current will flow. Do not rely on clips.

|

|

| f. |

Connect a voltmeter (0 to 20V) between the "B" terminal

and ground. Connect the (+) lead wire to the alternator

"B" terminal and (-) lead wire to a good ground.

|

| g. |

Connect the battery negative (-) terminal.

|

| h. |

Leave the engine hood open.

|

|

| (2) |

Test

| a. |

Check to see that the voltmeter reads the same value

as the battery voltage. If the voltmeter reads 0V, open

circuit in the wire between alternator "B" terminal and

battery (+) terminal or poor grounding is suspected.

|

| b. |

Start the engine and turn on the headlamps.

|

| c. |

Set the headlamps to high beam and the heater blower

switch to HIGH, quickly increase the engine speed to 2,500

rpm and read the maximum output current value indicated

by the ammeter.

|

• |

After the engine start up, the charging

current quickly drops. Therefore, the above

operation must be done quickly to read the

maximum current value correctly.

|

|

|

|

| (3) |

Result

| a. |

The ammeter reading must be higher than the limit value.

If it is lower despite the alternator output wire is in

good condition, remove the alternator from the vehicle and

test it.

|

Limit value : 60% of the voltage rate

|

|

• The nominal output current value is shown on

the nameplate affixed to the alternator body.

|

|

• |

The output current value changes with

the electrical load and the temperature

of the alternator itself. Therefore, the

nominal output current may not be obtained.

If such is the case, keep the headlamps

on to discharge the battery or use lights

of other vehicles to increase the electrical

load.

The nominal output current may not be

obtained if the temperature of the alternator

itself or ambient temperature is too high.

In such a case, reduce the temperature before

testing again.

|

|

|

| b. |

Upon completion of the output current test, lower the

engine speed to idle and turn off the ignition switch

|

| c. |

Disconnect the battery negative (-) terminal.

|

| d. |

Remove the ammeter and voltmeter and the engine tachometer.

|

| e. |

Connect the alternator output wire to the alternator

"B" terminal.

|

| f. |

Connect the battery negative (-) terminal.

|

|

|

| 3. |

Regulated Voltage Test

The purpose of this test is to check that the electronic voltage regulator

controls voltage correctly.

| (1) |

Preparation

| a. |

Prior to the test, check the following items and correct

if necessary.

Check that the battery installed on the vehicle is fully

charged. Refer to the "Battery" section for checking the

battery.

Check the alternator drive belt tension. Refer to the

"Inspect drive belt" section for checking the belt tension.

|

| b. |

Turn ignition switch to "OFF".

|

| c. |

Disconnect the battery negative (-) terminal.

|

| d. |

Connect a digital voltmeter between the "B" terminal

of the alternator and ground. Connect the (+) lead of the

voltmeter to the "B" terminal of the alternator. Connect

the (-) lead to good ground or the battery (-) terminal.

|

| e. |

Disconnect the alternator output wire from the alternator

"B" terminal.

|

| f. |

Connect a DC ammeter (0 to 150A) in series between the

"B" terminal and the disconnected output wire.Connect the

(-) lead wire of the ammeter to the disconnected output

wire.

|

| g. |

Connect the battery negative (-) terminal.

|

|

| (2) |

Test

| a. |

Turn on the ignition switch and check to see that the

voltmeter indicates the following value.

|

Voltage : Battery voltage

|

If it reads 0V, there is an open circuit in the wire

between the alternator "B" terminal and the battery and

the battery (-) terminal.

|

| b. |

Start the engine. Keep all lights and accessories off.

|

| c. |

Run the engine at a speed of about 2,500 rpm and read

the voltmeter when the alternator output current drops to

10A or less

|

|

| (3) |

Result

| a. |

If the voltmeter reading does not agree with the standard

value, the voltage regulator or the alternator is faulty.

|

Regulated Voltage : 11.7 - 15.3V

|

|

| b. |

If the voltmeter reading does not agree with the standard

value, the voltage regulator or the alternator is faulty.

|

| c. |

Disconnect the battery negative (-) terminal.

|

| d. |

Remove the voltmeter and ammeter.

|

| e. |

Connect the alternator output wire to the alternator

"B" terminal.

|

| f. |

Connect the battery negative (-) terminal.

|

|

|

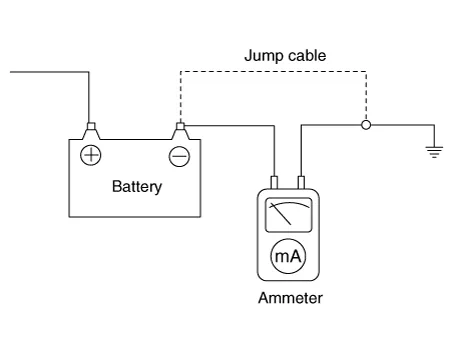

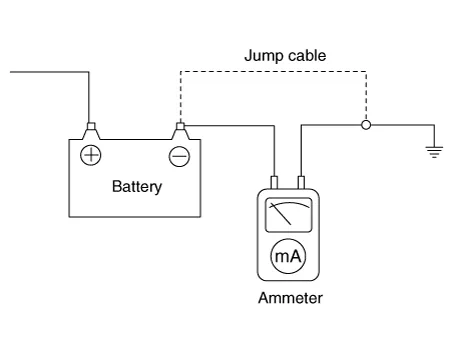

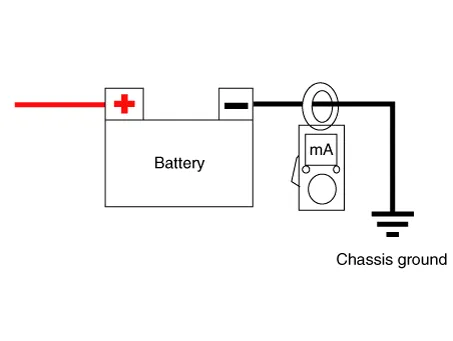

Vehicle parasitic current

inspection

[Using the Ammeter]

| 1. |

Turn the all electric devices OFF, and then turn the ignition switch

OFF.

|

| 2. |

Close all doors except the engine hood, and then lock all doors.

| (1) |

Disconnect the hood switch connector.

|

| (3) |

Close the doors or remove the door switches.

|

|

| 3. |

Wait for a few minutes until the vehicle’s electrical systems go to sleep

mode.

| •

|

For an accurate measurement of a vehicle parasitic current,

all electrical systems should go to sleep mode. (It takes

at least one hour or at most one day.) However, an approximate

vehicle parasitic current can be measured after 10-20 minutes.

|

|

|

| 4. |

Connect an ammeter in series between the battery (-) terminal and the

ground cable, and then disconnect the clamp from the battery (-) terminal

slowly.

| •

|

Be careful that the lead wires of an ammeter do not come

off from the battery (-) terminal and the ground cable to

prevent the battery from being reset. In case the battery

is reset, connect the battery cable again, and then start

the engine or turn the ignition switch ON for more than

10 sec. Repeat the procedure from No. 1.

To prevent the battery from being reset during the inspection:

|

| 1) |

Connect a jump cable between the battery (-) terminal

and the ground cable.

|

| 2) |

Disconnect the ground cable from the battery (-) terminal.

|

| 3) |

Connect an ammeter between the battery (-) terminal and

the ground cable.

|

| 4) |

After disconnecting the jump cable, read the current

value of the ammeter.

|

|

|

| 5. |

Read the current value of the ammeter.

| • |

If the parasitic current is over the limit value, search for

abnormal circuit by removing the fuses one by one and checking for

parasitic current.

|

| • |

Reconnect only the fuse suspected of parasitic current and search

for the trouble unit by removing the components connected to the

circuit one by one until the parasitic draw drops below limit value.

|

|

Limit value (after 10 - 20 min.) : Below 50mA

|

|

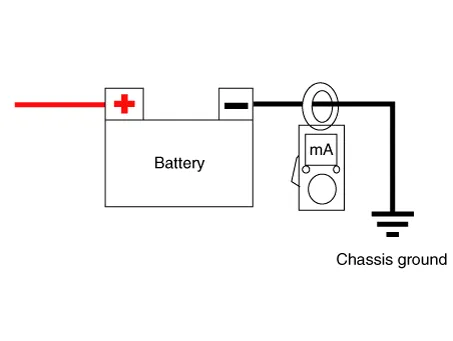

[Using the Clamp type Ammeter]

| 1. |

Turn the all electric devices OFF, and then turn the ignition switch

OFF.

|

| 2. |

Close all doors except the engine hood, and then lock all doors.

| (1) |

Disconnect the hood switch connector.

|

| (3) |

Close the doors or remove the door switches.

|

|

| 3. |

Wait for a few minutes until the vehicle’s electrical systems go to sleep

mode.

| •

|

For an accurate measurement of a vehicle parasitic current,

all electrical systems should go to sleep mode. (It takes

at least one hour or at most one day.) However, an approximate

vehicle parasitic current can be measured after 10 - 20

minutes.

|

|

|

| 4. |

Install the clamp type ammerter on battery negative (-) terminal.

|

| 5. |

Read the current value of the ammeter.

| • |

If the parasitic current is over the limit value, search for

abnormal circuit by removing the fuses one by one and checking for

parasitic current.

|

| • |

Reconnect only the fuse suspected of parasitic current and search

for the trouble unit by removing the components connected to the

circuit one by one until the parasitic draw drops below limit value.

|

|

Limit value (after 10 - 20 min.) : Below 50mA

|

|

Troubleshooting

Symptom

|

Suspect Area

|

Remedy

|

Charging warning indicator does not

light with ignition switch "ON" and

engine off.

|

Fuse blown

|

Check fuses

|

Light burned out

|

Replace light

|

Wiring connection loose

|

Tighten loose connection

|

Electronic voltage regulator

|

If light turns off, replace voltage regulator.

|

Charging warning indicator does not

go out with engine running. (Battery

requires frequent recharging)

|

Drive belt loose or worn

|

Adjust belt tension or replace belt

|

Battery cable loose, corroded or worn

|

Inspect cable connection, repair or replace cable

|

Electronic voltage regulator or alternator

|

If light turns off, replace voltage regulator or alternator

|

Wiring

|

Repair or replace wiring

|

Overcharge

|

Electronic voltage regulator

|

If light turns off, replace voltage regulator.

|

Voltage sensing wire

|

Repair or replace wiring

|

Discharge

|

Drive belt loose or worn

|

Adjust belt tension or replace belt

|

Wiring connection loose or short circuit

|

Inspect wiring connection, repair or replace wiring

|

Electronic voltage regulator or alternator

|

If light turns off, replace voltage regulator or alternator

|

Poor grounding

|

Inspect ground or repair

|

Worn battery

|

Replace battery

|

Specifications

Specification

Ignition System

Ignition Coil

Item

Specification

Rated Voltage (V)

12

Operation Voltage (V)

5 - 16

Item

Specification

Engine Speed (RPM)

1000

2000

3000

4000

5000

6000

Dwell Time (ms)

3.

Specifications

Specification

▷ 13.5V, 90A

Item

Specification

Rated voltage

13.

Other information:

Components and components location

Component Location

1. Cap

2. Nut

3. Wiper arm & blade

4. Cowl top cover

5. Bolt

6. Wiper motor & linkage assembly

7. Wiper motor connector

Repair procedures

Removal

1.

Description and operation

Description

The compressor is the power unit of the A/C system.

It is located on the side of engine block and driven by a V-belt of engine.

The compressor changes the low pressure and low temperature refrigerant gas into

the high pressure and high temperature refrigerant gas.