Kia Rio: Charging System / Battery Sensor

Description and operation

| Description |

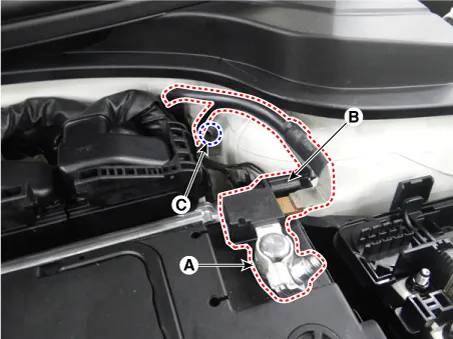

Vehicles have many control units that use more electricity. These units control their own system based on information from diverse sensors. It is important to have a stable power supply as there diverse sensors giving a variety of information. Battery sensor (A) is mounted on battery (-) terminal. It transmits battery voltage, current, temperature information to ECM. ECM controls generating voltage by duty cycle based on these signals.

Repair procedures

| Removal |

| 1. |

Turn the ignition switch OFF. |

| 2. |

Disconnect the battery negative (-) terminal (A). |

| 3. |

Disconnect the battery sensor connector (B). |

| 4. |

Remove the battery sensor by loosening the mounting bolts (C).

|

| Installation |

| 1. |

Install in the reverse order of removal.

|

| Battery Sensor Recalibration Procedure |

After reconnecting the battery negative cable, AMS function does not operates until the system is stabilized, about 4 hours. If disconnecting the negative (-) battery cable from the battery during repair work for the vehicle equipped with AMS function, Battery sensor recalibration procedure should be performed after finishing the repair work.

| 1. |

Turn the Iginition switch ON and OFF. |

| 2. |

Park the vehicle for about 4 hours with the hood and all doors closed. |

Specifications Specification ▷ AGM60L-DIN Item Specification Capacity [20HR/5HR] (AH) 60/48 Cold Cranking Amperage (A) 640 (SAE) / 640(EN) Reserve Capacity (Min) 100 • Model type description • Cold Cranking Ampere (CCA): Cold Cranking Amps is a rating used in the battery industry to define a battery's ability to start an engine in cold temperatures.

Description and operation Description Ignition timing is controlled by the electronic control ignition timing system. The standard reference ignition timing data for the engine operating conditions are pre-pro grammed in the memory of the ECM (Engine Control Module).

Other information:

Kia Rio 2017-2023 YB Service Manual: Immobilizer System

Schematic diagrams Circuit Diaram Description and operation Description The immobilizer system will disable the vehicle unless the proper ignition key is used, in addition to the currently available anti-theft systems such as car alarms, the immobilizer system aims to drastically reduce the rate of auto theft.

Kia Rio 2017-2023 YB Service Manual: Compressor Oil

Repair procedures Oil Specification 1. The HFC-134a system requires synthetic compressor oil (PAG) whereas the R-12 system requires mineral compressor oil. The two oils must never be mixed. 2. Compressor oil (PAG) varies according to compressor model.

Categories

- Manuals Home

- Kia Rio Owners Manual

- Kia Rio Service Manual

- Heating,Ventilation, Air Conditioning

- Body Electrical System

- Cooling System

- New on site

- Most important about car