Kia Rio: Engine Control System / Variable Force Solenoid (VFS)

Description and operation

| Description |

Continuous Variable Valve Timing (CVVT) system advances or retards the valve timing of the intake and exhaust valve in accordance with the ECM control signal which is calculated by the engine speed and load.By controlling CVVT, the valve over-lap or under-lap occurs, which makes better fuel economy and reduces exhaust gases (NOx, HC) and improves engine performance through reduction of pumping loss, internal EGR effect, improvement of combustion stability, improvement of volumetric efficiency, and increase of expansion work.This system consist of the Variable Force Solenoid (VFS) which supplies the engine oil to the cam phaser or cuts the engine oil from the cam phaser in accordance with the ECM PWM (Pulse With Modulation) control signal, the Cam Phaser which varies the cam phase by using the hydraulic force of the engine oil.Variable force solenoid (VFS) [intake] changes its force depending on the PWM duty to control the stroke of the CVVT oil control valve (OCV) [intake] bolt. The delivered oil rotates the rotor connected to the camshaft of the cam pager and rotates the camshaft to the engine rotating direction (intake advanced / exhaust retarded) or the opposite direction (intake retarded / exhaust advanced) to change the phase angle of the cam.

Variable Force Solenoid (VFS) [Bank 1 / Intake]

Schematic diagrams

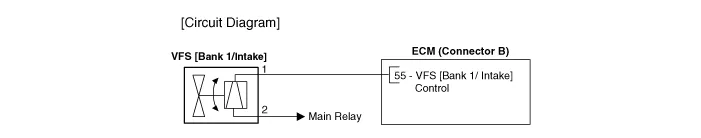

| Circuit Diagram |

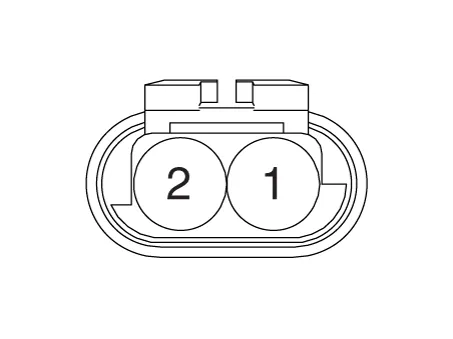

Harness Connector

Repair procedures

| Removal |

| 1. |

Turn ignition switch OFF and disconnect the battery negative (-) terminal |

| 2. |

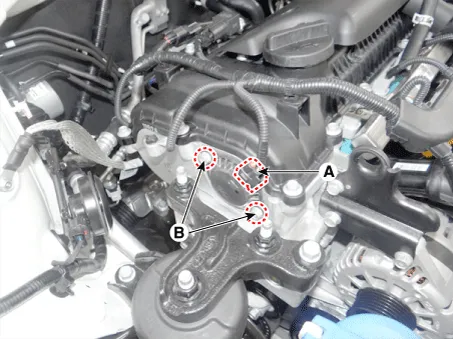

Disconnect the VFS connector (A). |

| 3. |

Remove the mounting bolts (B), and then remove the VFS from the engine.

|

| Installation |

|

| 1. |

Install in the reverse order of removal. |

Specifications Specification Item Specification Coil resistance (Ω) 30.0 ~ 35.0 [20°C(68°F)] Description and operation Description Variable Intake manifold Solenoid (VIS) valve is installed on the intake manifold.

Specifications Specification Item Specification Coil resistance (Ω) 30.0 - 35.0 [20°C(68°F)] Pin 2 Description and operation Description Engine coolant stop solenoid valve is installed on the upper side of engine and it is connected to engine coolant stop valve control actuator.

Other information:

Kia Rio 2017-2023 YB Service Manual: License Lamps

Repair procedures Removal 1. Disconnect the negative (-) battery terminal. 2. Remove the license lamp assembly (A) after pressing the locking pin. 3. Disconnect the license lamp connector (A).

Kia Rio 2017-2023 YB Service Manual: Heater Unit

Components and components location Component Location Components 1. Heater pipe cover 2. Heater core 3. Mode control actuator 4. Mode control actuator bracket 5. Mode control main lever 6.

Categories

- Manuals Home

- Kia Rio Owners Manual

- Kia Rio Service Manual

- Battery

- Rear Drum Brake

- Engine Mechanical System

- New on site

- Most important about car