Kia Rio: Hydraulic System / ON/OFF Solenoid Valve (SCSV-A)

Specifications

| Specification |

|

Item |

Specification |

|

Type |

Normal open |

|

Input voltage |

12 V |

|

Coil resistance |

3.5 ± 0.2 Ω (at 25°C, 77°F) |

|

Frequency |

50 Hz |

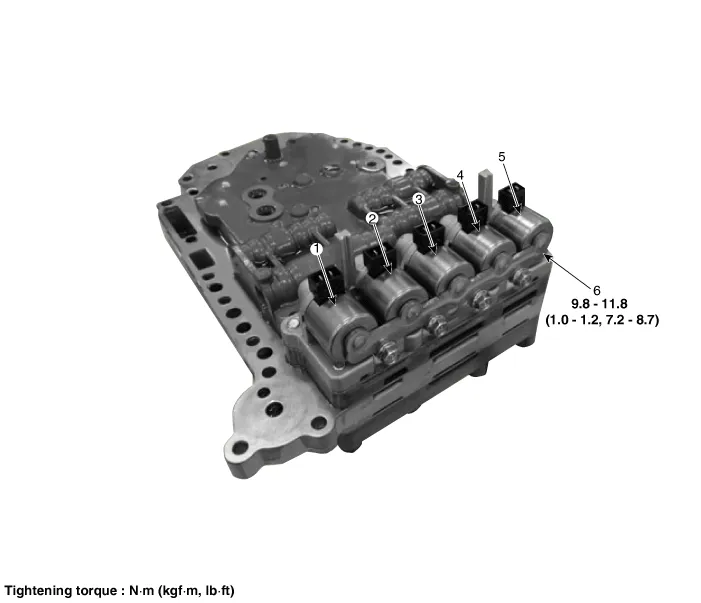

Components and components location

| Component Location |

| 1. Overdrive clutch control solenoid

valve (PCSV-A) 2. ON/OFF solenoid valve (SCSV-A) 3. Torque converter control solenoid valve (PCSV-D) |

4. Underdrive clutch control

solenoid valve (PCSV-C) 5. 24 brake control solenoid valve (PCSV-B) 6. Solenoid valve support bracket |

Description and operation

| Description |

| • |

ON/OFF solenoid valve is a PWM (Pulse Width Modulation) type. |

| • |

When TCM supplies current to solenoid valve, switch valve (OD, LR) is controlled by solenoid valve. |

Solenoid valve operation table

|

Range |

SCSV-A |

|

N, P |

● |

|

1 |

● |

|

2 |

|

|

3 |

|

|

4 |

|

|

R |

● |

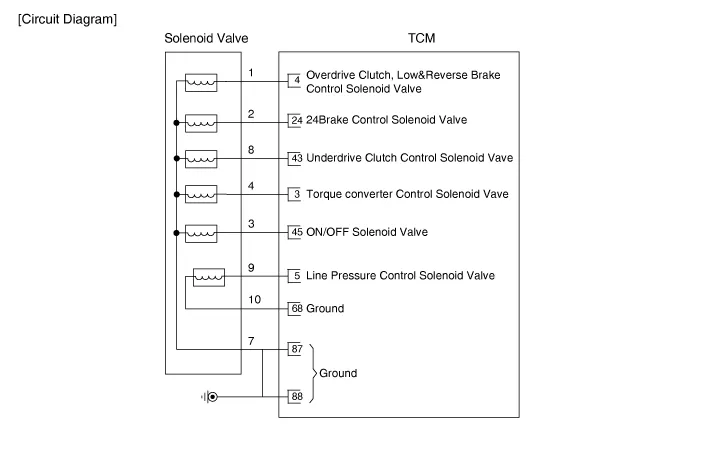

Schematic diagrams

| Circuit Diagram |

Repair procedures

| Inspection |

| 1. |

Switch "OFF" ignition. |

| 2. |

Remove the air cleaner. (Refer to Engine Mechanical System - "Air cleaner") |

| 3. |

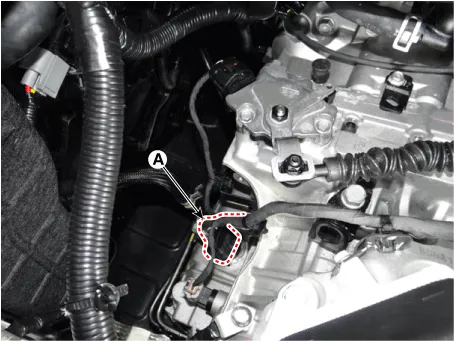

Disconnect the main connector (A).

|

| 4. |

Measure the resistance between ground terminal (7) and signal terminal (3).

|

| Removal |

| 1. |

Remove the valve body assembly (Refer to Hydraulic System - "Valve Body") |

| 2. |

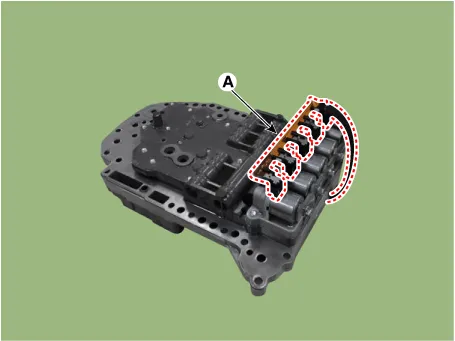

Disconnect the main harness (A).

|

| 3. |

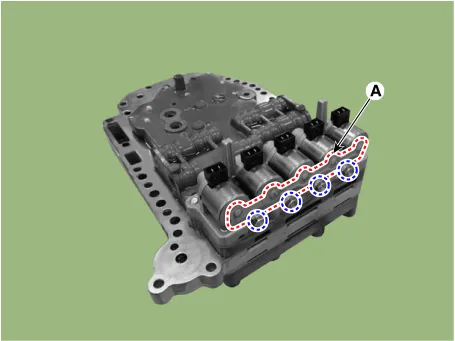

Remove solenoid valve support bracket (A) after loosening the bolts.

|

| 4. |

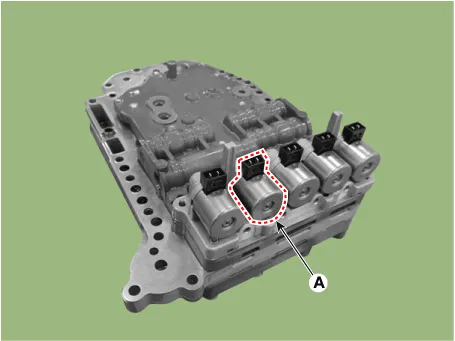

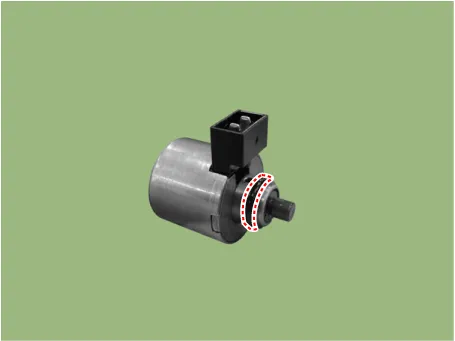

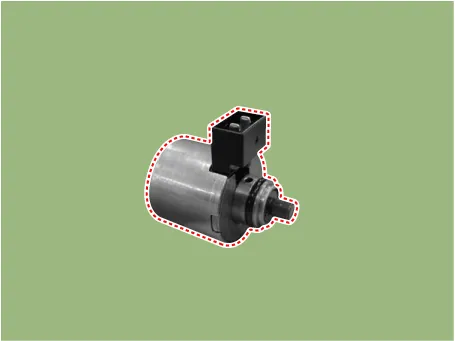

Remove the ON/OFF solenoid valve (A).

|

| Installation |

| 1. |

Install in the reverse order of removal. |

When installing, apply the ATF or petroleum jelly to the O-ring to prevent damage.

|

Specifications Specification Item Specification Type Normal open Input voltage 12 V Coil resistance 3.

Repair procedures Inspection Automatic Transaxle Fluid (ATF) Level Check 1. Place the vehicle on a level ground. 2.

Other information:

Kia Rio 2017-2023 YB Service Manual: Compressor Oil

Repair procedures Oil Specification 1. The HFC-134a system requires synthetic compressor oil (PAG) whereas the R-12 system requires mineral compressor oil. The two oils must never be mixed. 2. Compressor oil (PAG) varies according to compressor model.

Kia Rio 2017-2023 YB Service Manual: Blower Motor

Repair procedures Inspection 1. Connect the battery voltage and check the blower motor rotation. 2. If the blower motor does not operate well, substitute with a known-good blower motor and check for proper operation.

Categories

- Manuals Home

- Kia Rio Owners Manual

- Kia Rio Service Manual

- Steering System

- Engine Oil

- General Information

- New on site

- Most important about car