Kia Rio: Engine Control System / Knock Sensor (KS)

Specifications

| Specification |

Knock Sensor (KS)

|

Item |

Specification |

|

Resistance(MΩ) |

4.87 |

|

Capacitance (pF) |

950 ~ 1,350 |

|

Type |

Piezo-electricity |

|

Pin |

2 |

Description and operation

| Description |

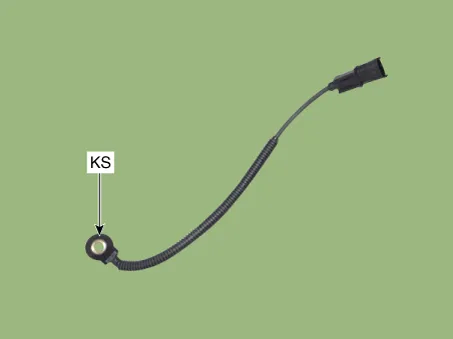

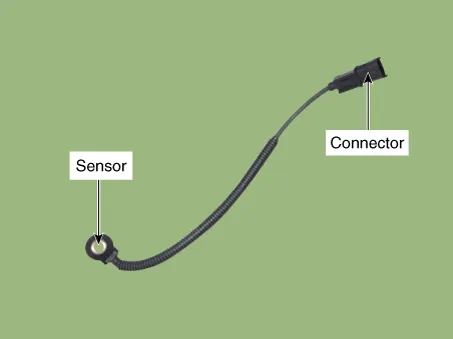

Knocking is a phenomenon characterized by undesirable vibration and noise and can cause engine damage. Knock Sensor (KS) is installed on the cylinder block and senses engine knocking.

When knocking occurs, the vibration from the cylinder block is applied as pressure to the piezoelectric element. At this time, this sensor transfers the voltage signal higher than the specified value to the ECM and the ECM retards the ignition timing. If the knocking disappears after retarding the ignition timing, the ECM will advance the ignition timing. This sequential control can improve engine power, torque and fuel economy.

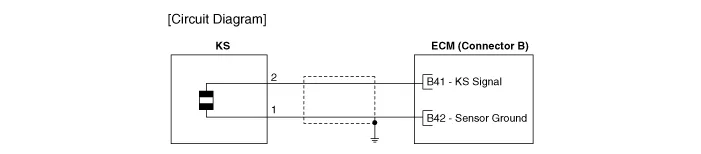

Schematic diagrams

| Circuit Diagram |

Repair procedures

| Removal |

| 1. |

Turn ignition switch OFF and disconnect the battery negative (-) terminal. |

| 2. |

Remove the intake manifold. (Refer to Engine Mechanical System - "Intake Manifold") |

| 3. |

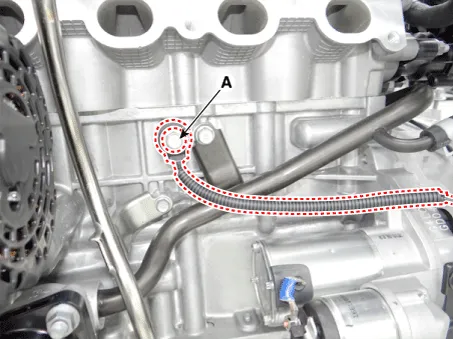

Remove the installation bolt (A), and then remove the sensor from the cylinder block.

|

| Installation |

|

| 1. |

Installation is reverse of removal. |

Specifications Specification Camshaft Position Sensor (CMPS) Item Specification Type Hall effect type Output Pulse (V) 0 ~ 5 Air Gap [mm (in.

Specifications Specification Heated Oxygen Sensor (HO2S) HO2S [Bank 1/Sensor 1] Item Specification Heater Resistance (Ω) Approximately 9.

Other information:

Kia Rio 2017-2023 YB Service Manual: Hazard Lamp Switch

Repair procedures Inspection 1. Check for continuity between terminals. If the continuity is not as specified, replace the hazard lamp switch. No. Description No.

Kia Rio 2017-2023 YB Service Manual: Compressor Oil

Repair procedures Oil Specification 1. The HFC-134a system requires synthetic compressor oil (PAG) whereas the R-12 system requires mineral compressor oil. The two oils must never be mixed. 2. Compressor oil (PAG) varies according to compressor model.

Categories

- Manuals Home

- Kia Rio Owners Manual

- Kia Rio Service Manual

- Timing Chain

- Engine Oil

- General Information

- New on site

- Most important about car