Kia Rio: Automatic Transaxle Control System / Transaxle Control Module (TCM)

Description and operation

| Description |

The module receives and processes signals from various sensors and implements a wide range of transaxle controls to ensure optimal driving conditions for the driver.

Functions

| • |

Monitors the vehicle's operating conditions to determine the optimal gear setting. |

| • |

Performs a gear change if the current gear setting differs from the identified optimal gear setting. |

| • |

Determines the need for torque converter clutch activation and engages the clutch accordingly. |

| • |

Calculates the optimal line pressure level by constantly monitoring the torque level and adjusts the pressure accordingly. |

| • |

Diagnoses the faults and failures for automatic transaxle. |

Schematic diagrams

| TCM Terminal Function |

Connector [A]

|

Pin |

Description |

|

3 |

PCSV-D |

|

4 |

PCSV-A |

|

5 |

LINE_VFS |

|

24 |

PCSV-B |

|

43 |

PCSV-C |

|

45 |

SCSV-A |

|

54 |

Manual mode "select" switch |

|

57 |

Inhibitor switch "D" input |

|

58 |

Inhibitor switch "R" input |

|

62 |

Manual mode "up" switch |

|

64 |

Power |

|

68 |

Ground |

|

79 |

Oil temperature sensor (-) |

|

80 |

Oil temperature sensor (+) |

|

84 |

Inhibitor switch "P" input |

|

85 |

Power |

|

87 |

Ground |

|

88 |

Ground |

|

99 |

Output speed sensor (+) signal |

|

100 |

Input speed sensor (+) signal |

|

104 |

Inhibitor switch "N" input |

|

105 |

Manual mode "down" switch |

Connector [K]

|

Pin |

Description |

|

5 |

Engine control relay "ON" input |

|

43 |

Output speed sensor ground |

|

82 |

Input speed sensor ground |

| Circuit Diagram |

Repair procedures

| Inspection |

| 1. |

TCM ground circuit test : Measure the resistance between TCM and chassis ground. (Inspect the terminal connected to the chassis ground with the back of harness connector as the inspection point of TCM side.)

|

| 2. |

TCM connector test : Disconnect the TCM connector and visually check the ground terminals on TCM side and harness side for bent pins or poor contact pressure. |

| 3. |

If problem is not found in Steps 1 and 2, the TCM could be faulty. If so, replace the TCM with a new one, and then check the vehicle again. If the vehicle operates normally then the problem was likely with the TCM. |

| 4. |

Reinspection of original TCM : Install the original TCM (probably broken) into a known-good vehicle and check the vehicle. If the problem occurs again, replace the original TCM with a new one. If the problem does not reoccur, this is an intermittentproblem and other part may be faulty. |

| Removal |

| 1. |

Remove the battery. (Refer to Engine Electrical System - "Battery") |

| 2. |

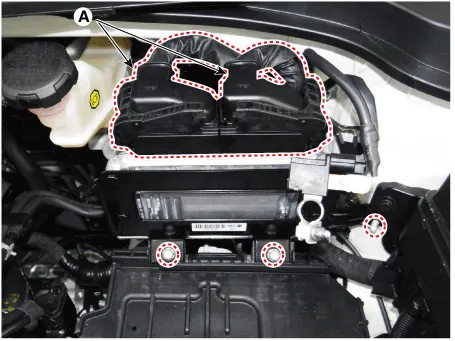

Disconnect the TCM connectors (A) and then remove the TCM after loosening the bolts and nut.

|

| Installation |

| 1. |

Install in the reverse order of removal. |

|

Description and operation Description Automatic transaxle control system relies on various measurements to determine the current control status and determine the necessary compensation values.

Specifications Specification Item Specification Type *NTC thermistor Temp.

Other information:

Kia Rio 2017-2023 YB Service Manual: Parking Assist Sensor

Components and components location Components Repair procedures Removal 1. Disconnect the negative (-) battery terminal. 2. Remove the rear bumper assembly. (Refer to Body - "Rear Bumper Assembly") 3.

Kia Rio 2017-2023 YB Service Manual: Smart Key

Repair procedures Smart Key Smart Key Code Saving 1. Connect the DLC cable of KDS/GDS to the data link connector (16 pins) in driver side crash pad lower panel, turn the power on KDS/GDS. 2. Select the vehicle model and then do "Smart key code saving".

Categories

- Manuals Home

- Kia Rio Owners Manual

- Kia Rio Service Manual

- Engine Oil and Filter

- Maintenance

- Engine Mechanical System

- New on site

- Most important about car