Kia Rio: Clutch System / Clutch Release Cylinder

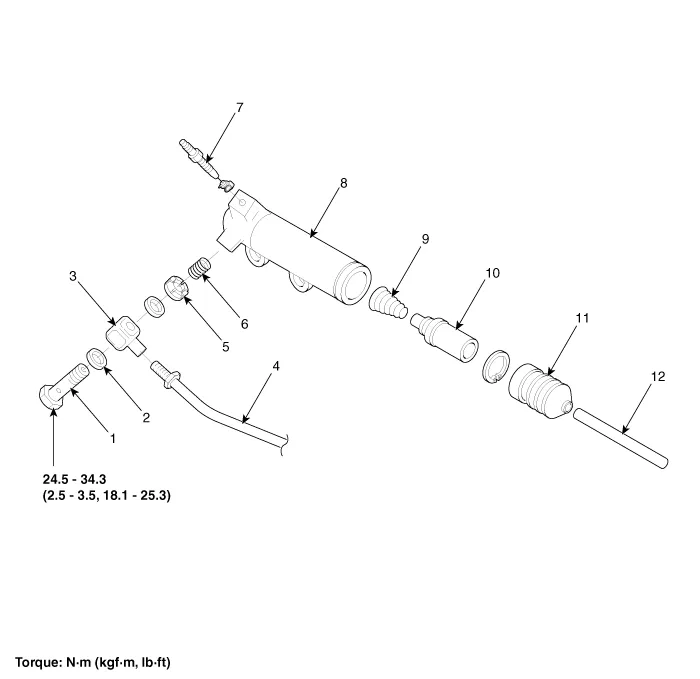

Components and components location

| Components |

| 1. Union bolt 2. Gasket 3. Tube joint 4. Clutch tube 5. Valve plate 6. Valve spring |

7. Bleeder screw 8. Release cylinder 9. Return spring 10. Piston 11. Boot 12. Push rod |

Repair procedures

| Removal |

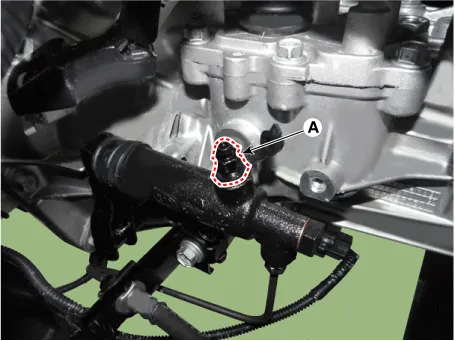

[Gasoline 1.2]

| 1. |

Drain the brake fluid through the bleed plug (A).

|

| 2. |

Loosen the release cylinder bolts (A) and then clutch tube nut (B) after removing release cylinder assembly (C ).

|

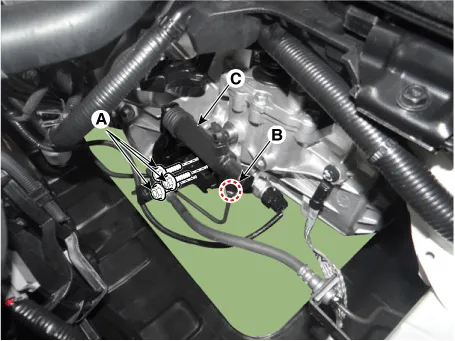

[Gasoline 1.0 T-GDI, 1.4, Diesel 1.4]

| 1. |

Drain the brake fluid through the bleed plug (A).

|

| 2. |

Loosen the release cylinder bolts (A) and then clutch tube nut (B) after removing release cylinder assembly ©.

|

| Installation |

| 1. |

Install in the reverse order of removal.

|

| Inspection |

| 1. |

Check the clutch release cylinder for fluid leakage. |

| 2. |

Check the clutch release cylinder boot for damage. |

| Adjustment |

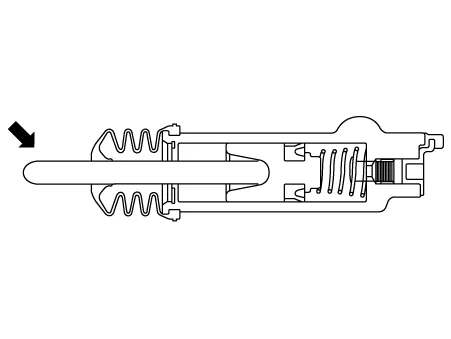

Clutch Release Cylinder Air Bleeding Procedure

Use the specified fluid. Avoid mixing different brands of fluid. |

| 1. |

After disconnecting a cap from the clutch release cylinder air bleeder, insert a vinyl hose in the plug. |

| 2. |

Refill the clutch master cylinder with the specified fluid.

|

| 3. |

Loosening the plug screw, press and release the clutch pedal about 10 times. |

| 4. |

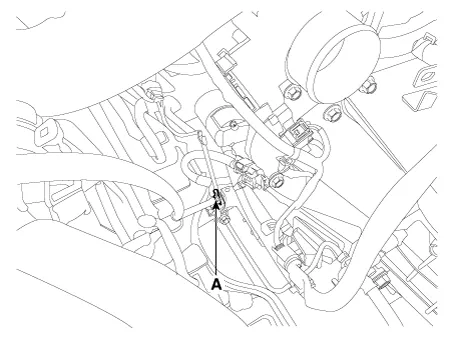

Tighten the plug (A) during the clutch pedal pressed. Afterwards, raise the pedal with a hand. |

| 5. |

After pressing the clutch pedal 3 times more, loosen the plug (A) and re-tighten it with the pedal pressed. Raise it again, then.

|

| 6. |

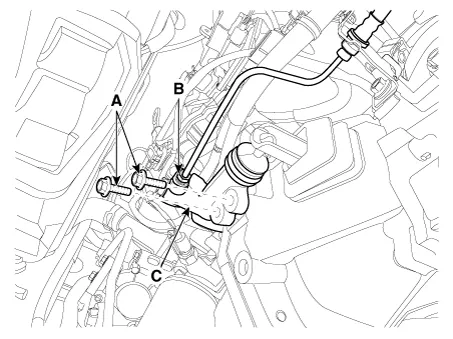

Repeat the step 4 two or three times. (until there is no bubble in the fluid) [Gasoline 1.2]

[Gasoline 1.0 T-GDI, 1.4, Diesel 1.4]

|

| 7. |

Refill the clutch master cylinder with the specified fluid. |

Components and components location Components [Gasoline 1.2, 1.4] 1. Clutch pedal assembly 2. Ignition lock and clutch switch 3.

Components and components location Components 1. Clutch release fork 2. Clutch cover assembly 3. Clutch disk assembly 4.

Other information:

Kia Rio 2017-2023 YB Service Manual: Instrument Cluster

Components and components location Components [Standard Type ("3.5")] [Supervision Type ("3.5")] Connector Pin Information Connector A No.

Kia Rio 2017-2023 YB Service Manual: Heater & A/C Control Unit (FATC)

Components and components location Components Connector Pin Function No. Connector A Connector B 1 Battery ⁻ 2 ISG battery (+) ⁻ 3 Illumination (+) ⁻

Categories

- Manuals Home

- Kia Rio Owners Manual

- Kia Rio Service Manual

- Coolant

- Maintenance

- Body Electrical System

- New on site

- Most important about car