Kia Rio: Lubrication System / Oil Pan

Components and components location

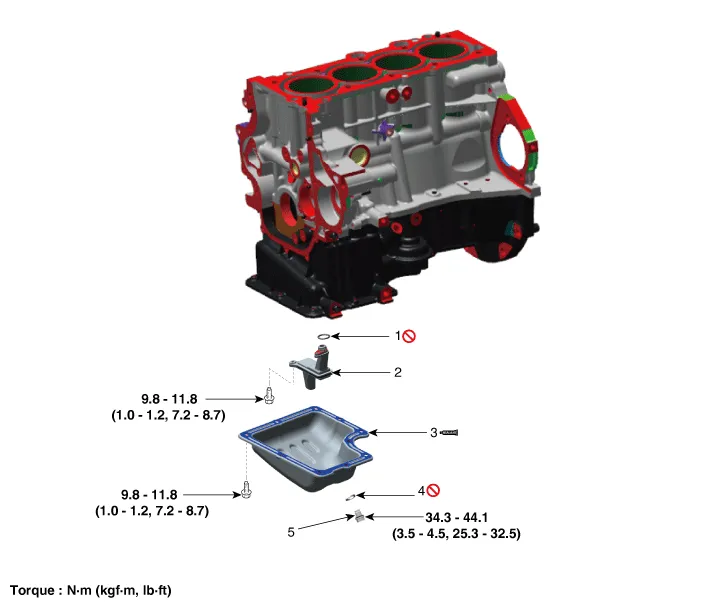

| Components |

| 1. Oil screen O-ring 2. Oil screen 3. Oil pan |

4. Drain plug gasket 5. Drain plug |

Repair procedures

| Removal |

| 1. |

Remove the engine room under cover. (Refer to Engine And Transaxle Assembly - "Engine Room Under Cover") |

| 2. |

Drain engine oil. (Refer to Lubrication System - "Engine Oil") |

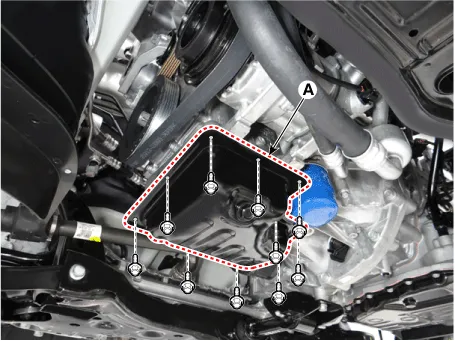

| 3. |

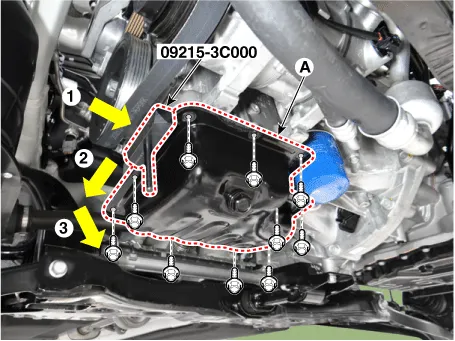

Remove the oil pan (A). Insert the blade of SST (09215-3C000) between the ladder frame and the oil pan. Cut off applied sealer and remove the oil pan.

|

| 4. |

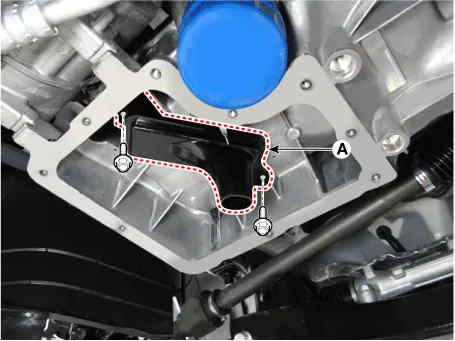

Remove the oil screen (A).

|

| Installation |

| 1. |

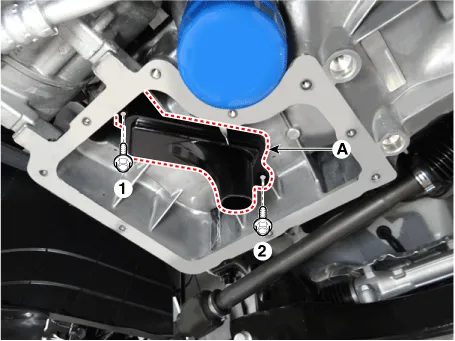

Install the oil screen (A), with a new O-ring. Tighten the bolts with the order blow.

|

| 2. |

Install the lower oil pan.

|

| 3. |

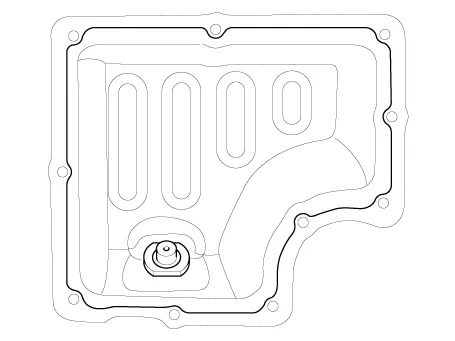

Install the lower oil pan (A).

Uniformly tighten the bolts in several passes.

|

| 4. |

Refill engine with engine oil. |

Repair procedures Removal and Installation 1. Disconnect the oil pressure switch connector (A) and then remove the oil pressure switch (B).

Repair procedures Removal and Installation 1. Remove the oil level gauge (A). 2. Remove the intake manifold.

Other information:

Kia Rio 2017-2023 YB Service Manual: Seat Heater Switch

Components and components location Components 1. Driver side seat heater switch 2. Passenger side seat heater switch Description and operation Description Seat Heater Smart Control Technology • To prevent low temperature burn, seat heater temperature will autom

Kia Rio 2017-2023 YB Service Manual: Cluster Ionizer (FATC only)

Description and operation Description The cluster ionizer helps to clean up odors in the vehicle or from the air-conditioner system. When the ignition switch ON, the inoizer runs a "CLEAN" mode and then a "ION" mode, switching every about 15 minutes.

Categories

- Manuals Home

- Kia Rio Owners Manual

- Kia Rio Service Manual

- Body Electrical System

- Motor Driven Power Steering

- Cooling System

- New on site

- Most important about car