Kia Rio: Manual Transaxle System / Manual Transaxle

Components and components location

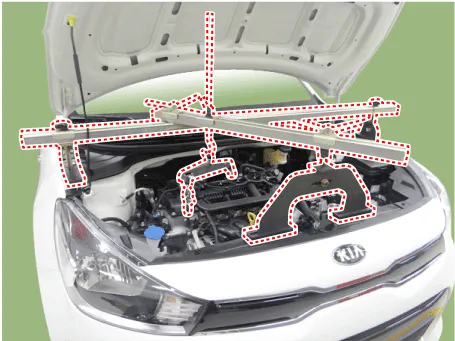

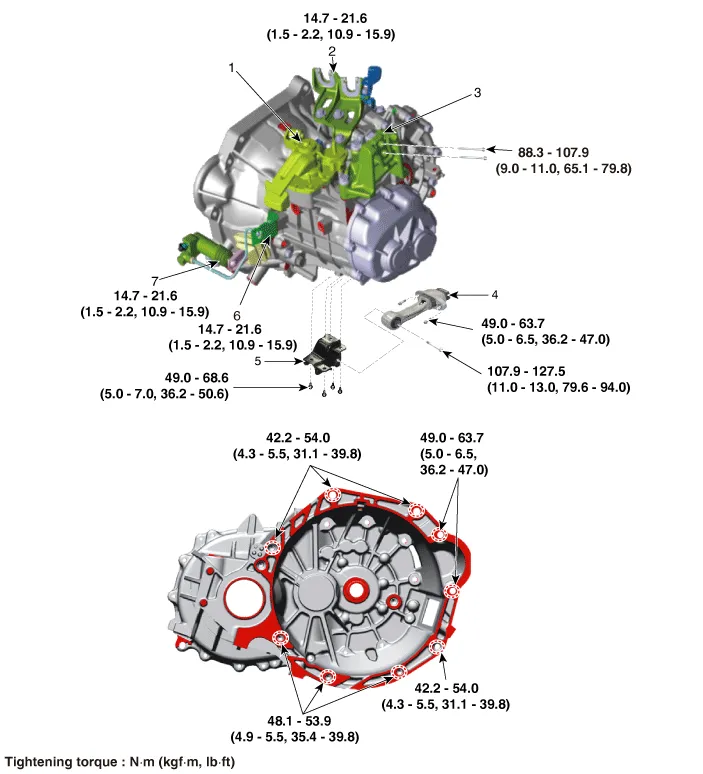

| Components |

|

1. Control shaft complete 2. Control cable bracket 3. Transaxle support bracket 4. Roll rod bracket |

5. Roll rod support bracket 6. Clutch tube bracket 7. Clutch release cylinder assembly |

Repair procedures

| Removal |

| 1. |

Remove the air cleaner assembly. (Refer to Engine Mechanical System - "Air Cleaner") |

| 2. |

Remove the battery and battery tray. (Refer to Engine Electrical System - "Battery") |

| 3. |

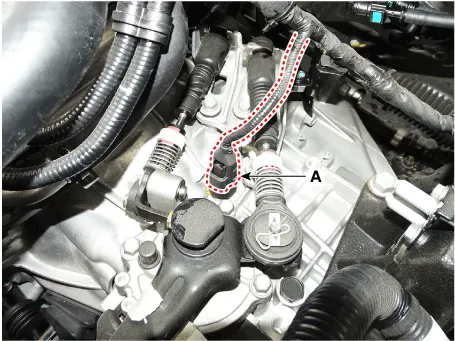

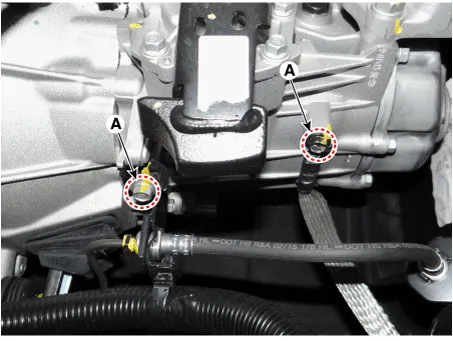

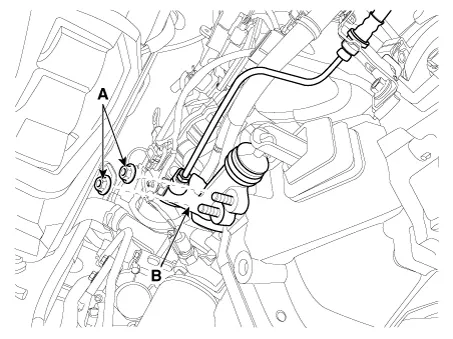

Disconnect the back up lamp switch (A).

|

| 4. |

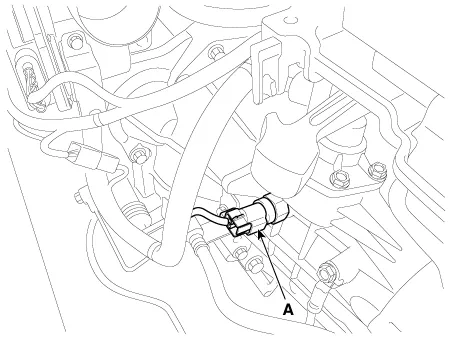

Disconnect the neutral switch connector (A).

|

| 5. |

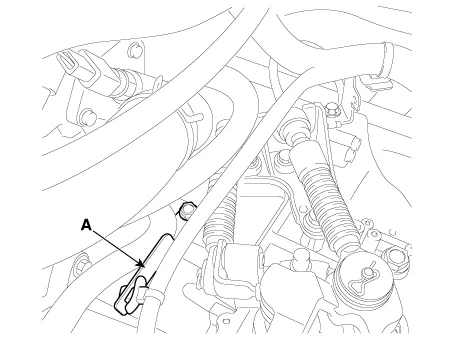

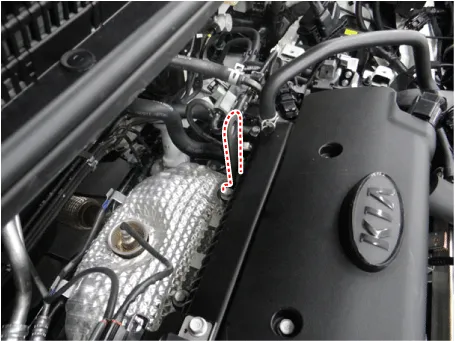

Remove the wiring from the bracket (A).

|

| 6. |

Remove the control cable.

|

| 7. |

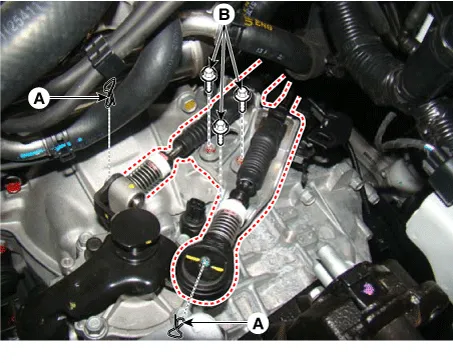

Remove the ground bolt (A) and clutch tube bracket bolt (B).

|

| 8. |

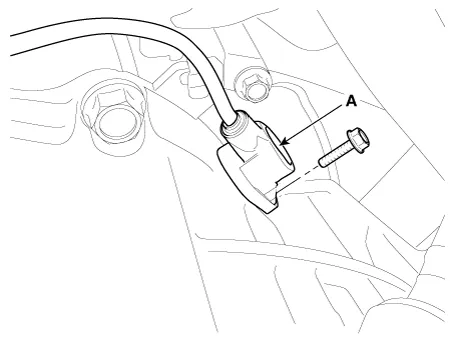

Remove the CKP sensor (A) after removing a bolt.

|

| 9. |

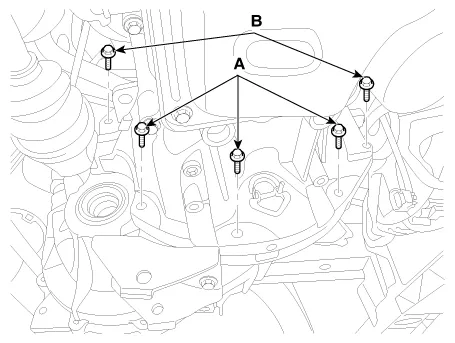

Loosen the starter mounting bolts (A) and the transaxle mounting bolts (B).

|

| 10. |

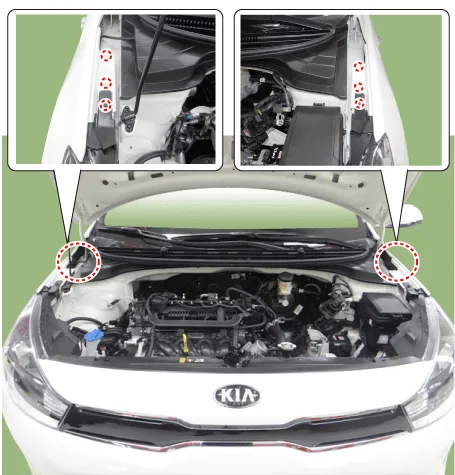

Install the engine support fixture on the engine room.

|

| 11. |

Support the transaxle safely on a jack.

|

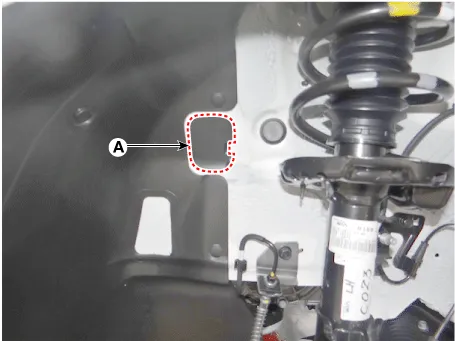

| 12. |

Remove the cover (A).

|

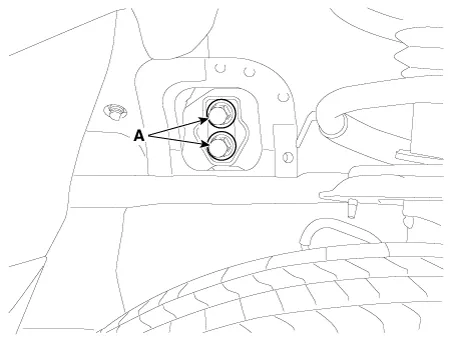

| 13. |

Remove the transaxle mounting bracket bolts (A).

|

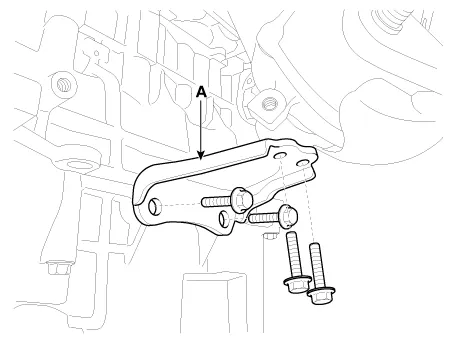

| 14. |

Remove the transaxle support bracket (A).

|

| 15. |

Remove the under cover. (Refer to Engine Mechanical System - "Engine Room Under Cover") |

| 16. |

Remove the drive shaft assembly. (Refer to Driveshaft and Axle - "Front Driveshaft") |

| 17. |

Remove the exhaust manifold stay (A).

|

| 18. |

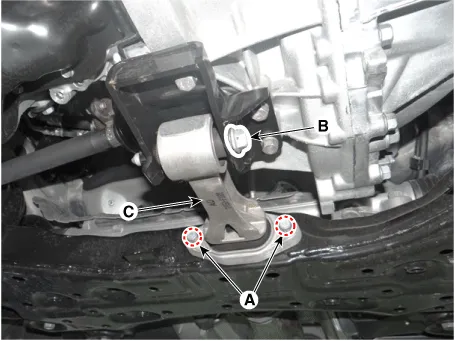

Remove the clutch release cylinder assembly (B) after removing the nuts (A).

|

| 19. |

Remove the roll rod bracket (C) after removing bolt (A,B).

|

| 20. |

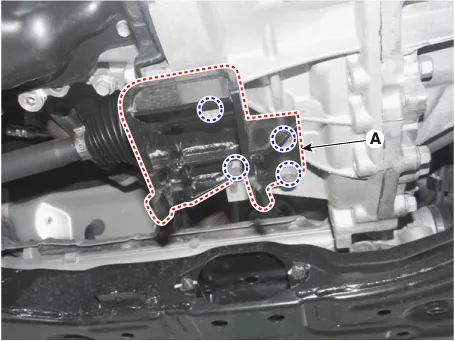

Remove the roll rod support bracket (A).

|

| 21. |

Support the transaxle safely on a jack. |

| 22. |

Loosen the transaxle lower mounting bolts (A, B).

|

| 23. |

After separating the transaxle from the engine, remove the transaxle by lowering the jack slowly.

|

| Installation |

In case of oil leakage due to damaged differential oil seal, replace the oil seal with a new one by using special tools (09431-26100, 09231-H1100). |

| 1. |

Install in the reverse order of removal. |

Repair procedures Inspection Manual Transaxle Oil Level Check 1. Stop the engine and then raise the vehicle using the lift.

Specifications Specifications Item Specified Type ON/OFF Operating condition Reverse gear Operating voltage 10V - 15V Operating temperatures -30°C to 100°C [-30°F to 212°F]" Components and components location Component Location 1.

Other information:

Kia Rio 2017-2023 YB Service Manual: Overhead Console Lamp

Repair procedures Inspection 1. Remove the overhead console lamp assembly then check for continuity between terminals. If the continuity is not as specified, replace the map lamp switch. Removal 1.

Kia Rio 2017-2023 YB Service Manual: Blower Resistor (MANUAL)

Repair procedures Inspection 1. Measure the resistance between the terminals. 2. The measured resistance is not within specification, the blower resistor must be replaced. (After removing the resistor) Replacement 1.

Categories

- Manuals Home

- Kia Rio Owners Manual

- Kia Rio Service Manual

- Engine Mechanical System

- Body Electrical System

- Steering System

- New on site

- Most important about car