Kia Rio: Brake System / Front Disc Brake

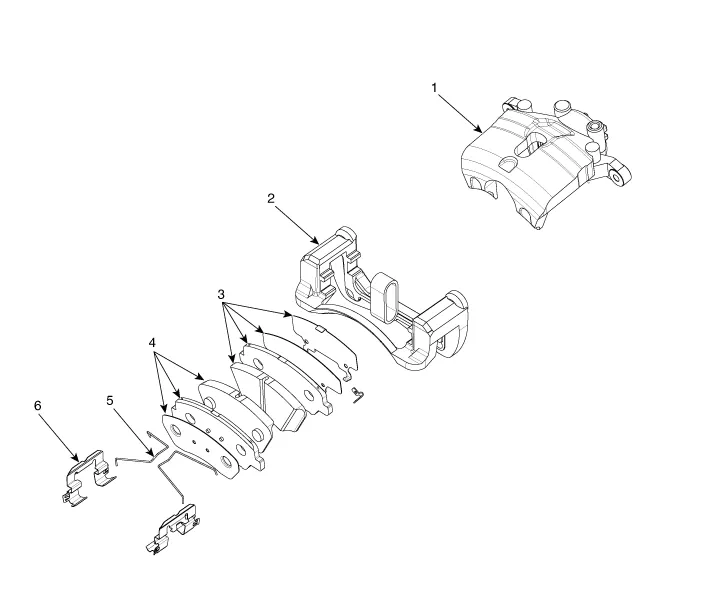

Components and components location

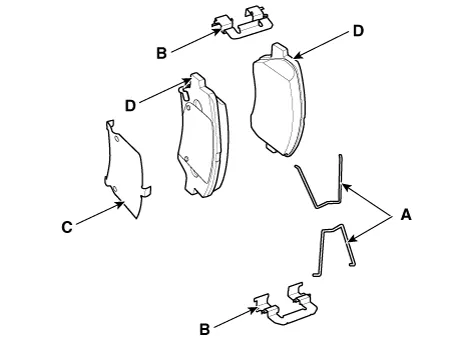

| Components |

| 1. Caliper body 2. Caliper carrier 3. Brake pad assembly [IN] |

4. Brake pad assembly [OUT]

5. Pad return spring 6. Pad liner |

Repair procedures

| Removal |

Brake Pad

| 1. |

Remove the front wheel & tire.

|

| 2. |

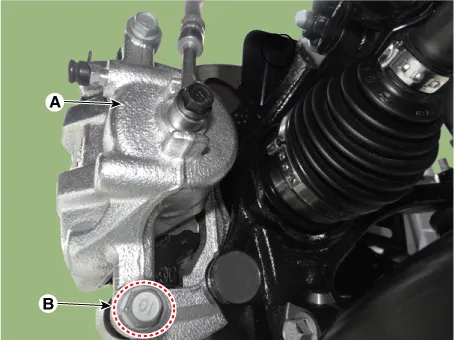

Loosen the guide rod bolt (B) and then pivot the caliper body (A) up out of the way.

|

| 3. |

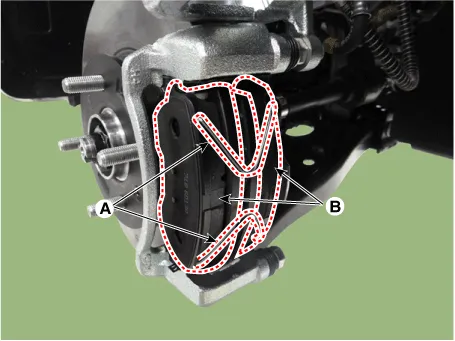

Remove the pad return spring (A) and then separate the brake pad (B).

|

Caliper Assembly

| 1. |

Remove the front wheel & tire.

|

| 2. |

Loosen the guide rod bolt (B) and then pivot the caliper body (A) up out of the way.

|

| 3. |

Remove the pad return spring (A) and then separate the brake pad (B).

|

| 4. |

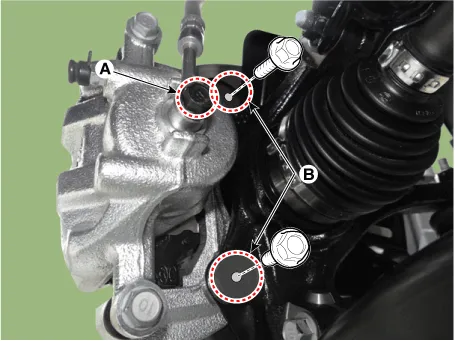

Loosen the bolts (A,B) and then remove the brake caliper.

|

Disc

| 1. |

Remove the front wheel & tire.

|

| 2. |

Loosen the guide rod bolt (B) and then pivot the caliper body (A) up out of the way.

|

| 3. |

Remove the pad return spring (A) and then separate the brake pad (B).

|

| 4. |

Loosen the bolts (A,B) and then remove the brake caliper.

|

| 5. |

Remove the brake disc after loosening the screw.

|

| Inspection |

Front brake disc thickness check

| 1. |

Check the brake pads for wear and fade. |

| 2. |

Check the brake disc for damage and cracks. |

| 3. |

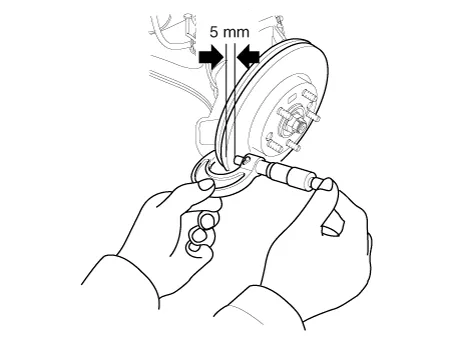

Remove all rust and contamination from the surface, and measure the disc thickness at 8 points, at least, at the same distance (5mm) apart from the brake disc outer circle.

|

| 4. |

If wear exceeds the limit, replace the discs and pad assembly left and right of the vehicle. |

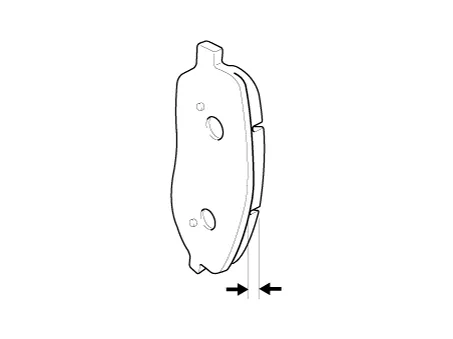

Front Brake Pad Check

| 1. |

Check the pad wear. Measure the pad thickness and replace it, if it is less than the specified value.

|

| 2. |

Check that grease is applied to sliding contact points and check the pad and backing metal for damage.

|

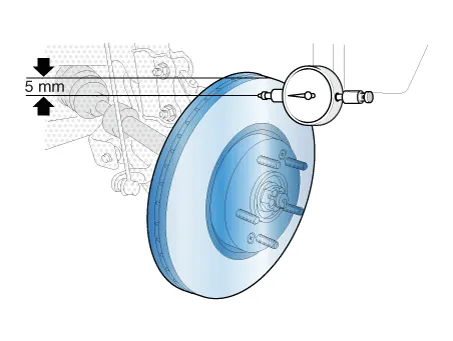

Front brake disc runout check

| 1. |

Place a dial gauge about 5mm (0.2 in.) from the outer circumference of the brake disc, and measure the runout of the disc.

|

| 2. |

If the runout of the brake disc exceeds the limit specification, replace the disc, and then measure the runout again. |

| 3. |

If the runout does not exceed the limit specification, install the brake disc after turning it 180° and then check the brake disc again for runout. |

| 4. |

If the runout cannot be corrected by changing the position of the brake disc, replace the brake disc. |

| Installation |

| 1. |

Install in the reverse order of removal. |

| 2. |

Use the SST (09581-11000) when installing the brake caliper assembly.

|

| 3. |

After installation, bleed the brake system. (Refer to Brake system - "Brake System") |

Components and components location Components 1. Brake member assembly 2. Stop lamp switch 3. Pedal assembly Repair procedures Removal 1.

Components and components location Components 1. Cable cuide & Lever 2. Caliper body 3. Torque member 4.

Other information:

Kia Rio 2017-2023 YB Service Manual: Instrument Cluster

Components and components location Components [Standard Type ("3.5")] [Supervision Type ("3.5")] Connector Pin Information Connector A No.

Kia Rio 2017-2023 YB Service Manual: Air Conditioning System

General safety information and caution Instructions When Handling Refrigerant 1. R-134a liquid refrigerant is highly volatile. A drop on the skin of your hand could result in localized frostbite. When handling the refrigerant, be sure to wear gloves.

Categories

- Manuals Home

- Kia Rio Owners Manual

- Kia Rio Service Manual

- Maintenance

- Motor Driven Power Steering

- Brake System

- New on site

- Most important about car