Kia Rio: Air Conditioning System / Condenser

Repair procedures

| Inspection |

| 1. |

Check the condenser fins for clogging and damage. If clogged, clean them with water, and blow them with compressed air. If bent, gently bend them using a screwdriver or pliers. |

| 2. |

Check the condenser connections for leakage, and repair or replace it, if required. |

| Replacement |

| 1. |

Recover the refrigerant with a recovery/recycling/charging station. |

| 2. |

Disconnect the negative (-) battery terminal. |

| 3. |

Remove the front bumper. (Refer to Body - "Front Bumper Assembly") |

| 4. |

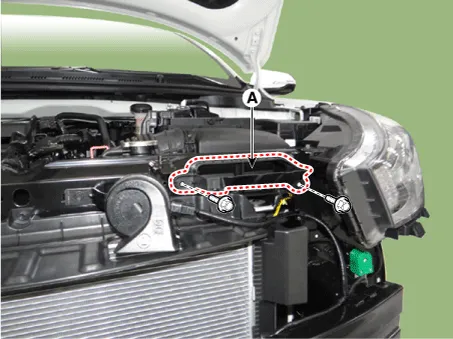

Remove the air intake shield (A) after loosening the bolts.

|

| 5. |

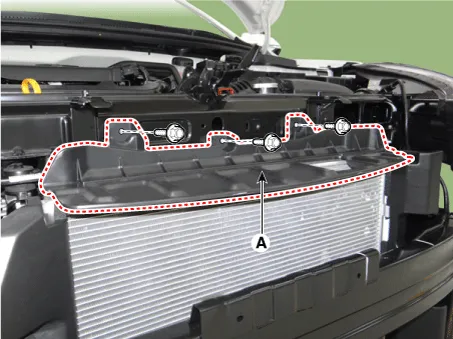

Remove the air upper guard (A) after loosening the bolts.

|

| 6. |

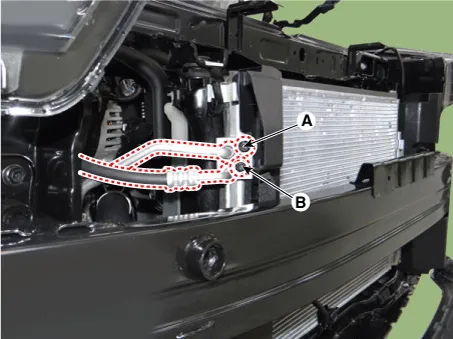

Remove the discharge line (A) and liquid line (B) after loosening the nuts.

|

| 7. |

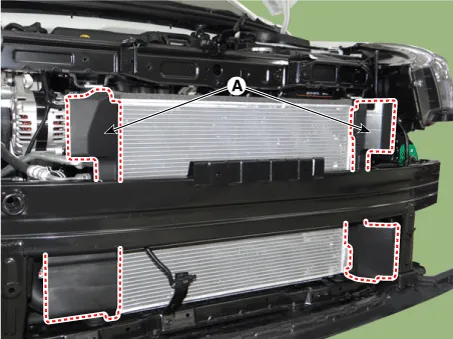

Loosen the mounting pin - type retainers and bolts, remove the side air guard (A).

|

| 8. |

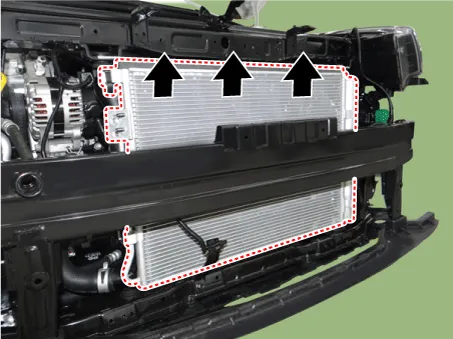

Remove the condenser.

|

| 9. |

Installation is the reverse order of removal.

|

Description and operation Description The compressor is the power unit of the A/C system. It is located on the side of engine block and driven by a V-belt of engine.

Repair procedures Replacement 1. Remove the condenser. 2. Remove the cap (B) on the bottom of the condenser with L wrench (A).

Other information:

Kia Rio 2017-2023 YB Service Manual: Smart Key System

Specifications Specifications Smart Key Unit Items Specification Rated voltage DC 12 V Operating voltage DC 9 - 16 V Operating temperature -31 - 167°F (-35 - 75°C) Load Max.

Kia Rio 2017-2023 YB Service Manual: Windshield Wiper-Washer Switch

Repair procedures Removal [BCM Type] 1. Disconnect the negative (-) battery terminal. 2. Remove the steering wheel. (Refer to Steering System - "Steering Wheel") 3.

Categories

- Manuals Home

- Kia Rio Owners Manual

- Kia Rio Service Manual

- Brake System

- General Information

- Suspension System

- New on site

- Most important about car