Kia Rio: Tires/Wheels / Alignment

Repair procedures

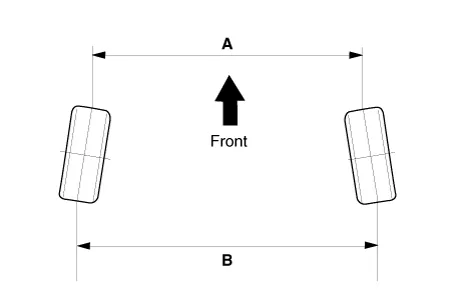

| Front wheel alignment |

When using a commercially available computerized wheel alignment equipment to inspect the front wheel alignment, always position the vehicle on a level surface with the front wheels facing straight ahead. Prior to inspection, make sure that the front suspension and steering system are in normal operating condition and that the tires are inflated to the specified pressure. |

Toe

|

B - A > 0: Toe in (+) B - A < 0: Toe out (-) |

Toe adjustment

| 1. |

Loosen the tie rod end lock nut. |

| 2. |

Remove the bellows clip to prevent the bellows from being twisted. |

| 3. |

Adjust the toe by screwing or unscrewing the tie rod. Toe adjustment should be made by turning the right and left tie rods by the same amount.

|

| 4. |

When completing the toe adjustment, install the bellows clip and tighten the tie rod end lock nut to specified torque.

|

| 5. |

Perform the Steering Angle Sensor calibration.

|

Camber and Caster

Camber and Caster are pre-set at the factory, so they do not need to be adjusted. If the camber and caster are not within the standard value, replace or repair the damaged parts and then inspect again.

|

Camber angle : (EU/AUS) -0.5°±0.5° (GEN) -0.4°±0.5° |

|

Caster angle : (EU/AUS) 4.65°±0.5° (GEN) 4.54°±0.5° |

Repair procedures Hub nut tightening sequence Tighten the hub nuts as follows. Tightening torque: 107.9 - 127.5 N·m (11.

Components and components location Components 1. HECU 2. Cluster 3. TPMS SET Switch 4. Wheel speed sensor 5.

Other information:

Kia Rio 2017-2023 YB Service Manual: Power Door Mirror Actuator

Components and components location Components 1. Side repeater lamp Repair procedures Inspection 1. Disconnect the negative (-) battery terminal. 2. Remove the front door quadrant inner cover (A).

Kia Rio 2017-2023 YB Service Manual: Smart Key Diagnostic

Repair procedures Inspection Self Diagnosis With Scan Tool It will be able to diagnose defects of SMART KEY system with KDS/GDS quickly. KDS/GDS can operates actuator forcefully, input/output value monitoring and self diagnosis. The following three features will be major problem in SMART KEY system.

Categories

- Manuals Home

- Kia Rio Owners Manual

- Kia Rio Service Manual

- Timing Chain

- Cooling System

- Motor Driven Power Steering

- New on site

- Most important about car