Kia Rio: Maintenance / Engine oil

Checking the engine oil level

■ Gamma II 1.6L MPI (Gasoline engine)

1. Be sure the vehicle is on level ground.

2. Start the engine and allow it to reach normal operating temperature.

3. Turn the engine off and wait for a few minutes (about 5 minutes) for the oil to return to the oil pan.

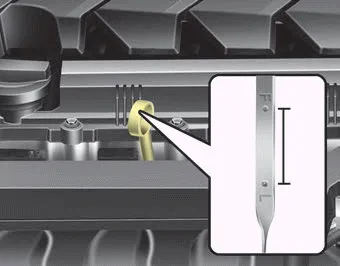

4. Pull the dipstick out, wipe it clean, and reinsert it fully.

WARNING - Radiator hose

Be very careful not to touch the radiator hose when checking or adding the engine oil as it may be hot enough to burn you.

5. Pull the dipstick out again and check the level. The level should be between F and L.

CAUTION - Replacing engine oil

Do not overfill the engine oil. It may damage the engine.

■ Gamma II 1.6L MPI (Gasoline engine)

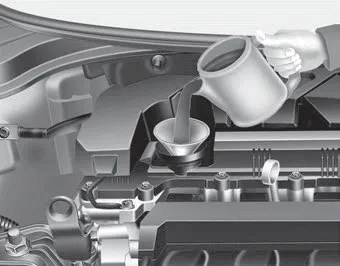

If it is near or at L, add enough oil to bring the level to F. Do not overfill.

Use a funnel to help prevent oil from being spilled on engine components.

Changing the engine oil and filter

Have engine oil and filter changed by an authorized Kia dealer according to the Maintenance Schedule at the beginning of this chapter.

WARNING - Used engine oil

Used engine oil may cause irritation or cancer of the skin if left in contact with the skin for prolonged periods of time. Always protect your skin by washing your hands thoroughly with soap and warm water as soon as possible after handling used oil.

When checking engine oil, engine coolant, brake fluid, and washer fluid, always be sure to clean the area around any filler plug, drain plug, or dipstick before checking or draining any lubricant or fluid.

The high-pressure cooling system has a reservoir filled with year round antifreeze coolant. The reservoir is filled at the factory. Check the antifreeze protection and coolant level at least once a year: at the beginning of the winter season, and before traveling to a colder climate.

Other information:

Kia Rio 2017-2023 YB Service Manual: Heater Unit

Components and components location Component Location Components 1. Heater pipe cover 2. Heater core 3. Mode control actuator 4. Mode control actuator bracket 5. Mode control main lever 6.

Kia Rio 2017-2023 YB Service Manual: Power Mosfet (FATC)

Repair procedures Inspection 1. Turn the ignition switch ON. 2. Manually operate the control switch and measure the voltage of blower motor. 3. Select the control switch to raise voltage until high speed.

Categories

- Manuals Home

- Kia Rio Owners Manual

- Kia Rio Service Manual

- Maintenance

- General Information

- Cooling System

- New on site

- Most important about car