Kia Rio: Cylinder Block / Cylinder Block

Repair procedures

| Disassembly |

|

|

| 1. |

Remove the engine assembly from the vehicle. (Refer to Engine and Transaxle Assembly - "Engine and Transaxle Assembly”) |

| 2. |

Remove the transaxle assembly from the engine assembly. (Refer to Manual Transaxle System - "Manual Transaxle") |

| 3. |

Remove the flywheel. (Refer to Cylinder Block - "Flywheel") |

| 4. |

Install the engine to engine stand for disassembly. |

| 5. |

Remove the timing chain. (Refer to Timing System - "Timing Chain”) |

| 6. |

Remove the intake manifold. (Refer to Intake and Exhaust System - "Intake Manifold") |

| 7. |

Remove the exhaust manifold. (Refer to Intake and Exhaust System - "Exhaust Manifold") |

| 8. |

Remove the cylinder head assembly. (Refer to Cylinder Head Assembly - "Cylinder Head") |

| 9. |

Remove the water pipe. (Refer to Cooling System - "Thermostat") |

| 10. |

Remove the water temperature control assembly. (Refer to Cooling System - "Thermostat") |

| 11. |

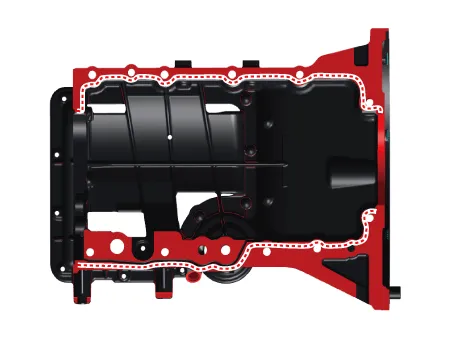

Remove the oil pan and oil screen. (Refer to Lubrication System - "Oil Pan") |

| 12. |

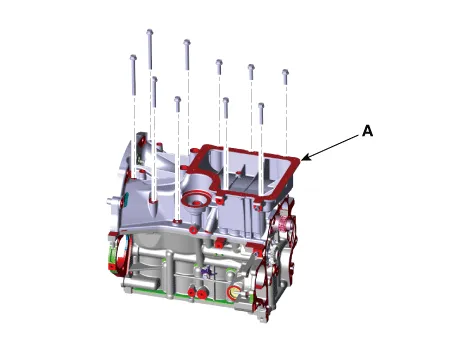

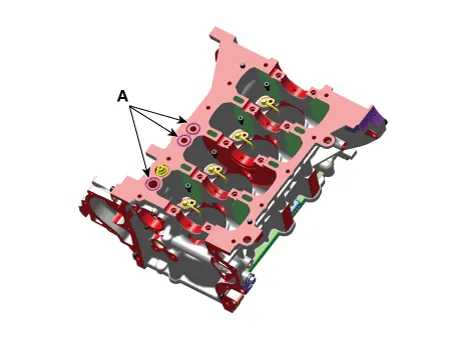

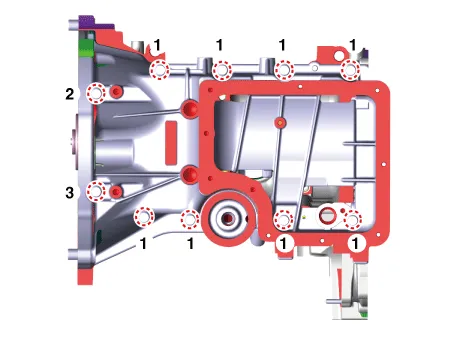

Remove the ladder frame (A). Insert the blade of SST (09215-3C000) between the cylinder block and the ladder frame. Cut off applied sealer and remove the ladder frame (A).

|

| 13. |

Remove the piston and connecting rod assemblies. (Refer to Cylinder Block - "Piston and Connecting Rod") |

| 14. |

Remove the crankshaft. (Refer to Cylinder Block - "Crankshaft") |

| 15. |

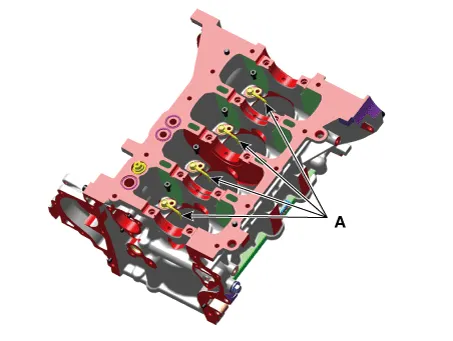

Remove the piston cooling oil jet (A).

|

| Inspection |

Cylinder Block

| 1. |

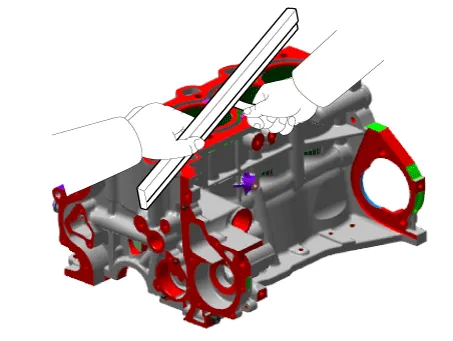

Remove the gasket material. Using a gasket scraper, remove all the gasket material from the top surface of the cylinder block. |

| 2. |

Clean the cylinder block. Using a soft brush and solvent, thoroughly clean the cylinder block. |

| 3. |

Inspect the top surface of the cylinder block for flatness. Using a precision straight edge and feeler gauge, measure the surface contacting the cylinder head gasket for warpage.

|

| 4. |

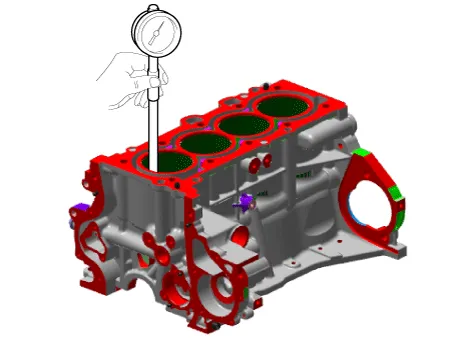

Inspect the cylinder bore. Visually check the cylinder for vertical scratchs. If deep scratchs are present, replace the cylinder block. |

| 5. |

Inspect the cylinder bore diameter. Using a cylinder bore gauge, measure the cylinder bore diameter at position in the thrust and axial direction.

|

| Reassembly |

| 1. |

Remove the crankshaft. (Refer to Cylinder Block - "Crankshaft") |

| 2. |

Remove the piston and connecting rod assemblies. (Refer to Cylinder Block - "Piston and Connecting Rod") |

| 3. |

Install the piston cooling oil jet (A).

|

| 4. |

Install the ladder frame.

|

| 5. |

Assemble the other parts in the reverse order of disassembly. |

Repair procedures Disassembly • Use fender covers to avoid damaging painted surfaces.

Other information:

Kia Rio 2017-2023 YB Service Manual: Instrument Cluster

Components and components location Components [Standard Type ("3.5")] [Supervision Type ("3.5")] Connector Pin Information Connector A No.

Kia Rio 2017-2023 YB Service Manual: Rear Wiper/Washer

C

Categories

- Manuals Home

- Kia Rio Owners Manual

- Kia Rio Service Manual

- Timing Chain

- Maintenance

- Engine Mechanical System

- New on site

- Most important about car